Custom injection molding services for plastic prototypes and on-demand plastic production parts.

Get a free injection molding quotation and design feedback within hours.

- Home

- Capabilities

- Injection Molding

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts by injecting molten material (usually plastic) into a mold. It's one of the most common ways to mass-produce plastic parts with high precision and repeatability.

How Injection Molding Works (Step by Step):

1.Material Feeding

Plastic in the form of small pellets (granules) is fed into a heated barrel through a hopper.

2.Melting (Plasticizing)

A rotating screw inside the barrel pushes the pellets forward while heating elements melt them into a viscous liquid (molten plastic).

3.Injection

The screw acts like a plunger and rapidly injects the molten plastic under high pressure (typically 10,000–30,000 psi) into a closed metal mold (called a "tool" or "die").

4.Packing & Cooling

Additional material is forced in to compensate for shrinkage as the plastic cools and solidifies inside the cooled mold (cooling time is usually the longest part of the cycle).

5.Ejection

The mold opens, and ejector pins push the finished part out. The mold closes again, and the cycle repeats.

A single cycle can take from a few seconds to a couple of minutes, depending on part size and material.

Key Components of an Injection Molding System:

A.Injection molding machine (with hopper, barrel, screw, and hydraulic/clamping unit)

B.Mold (tool) – usually made of hardened steel or aluminum, consisting of two halves (core and cavity)

C.Material – most commonly thermoplastics (e.g., ABS, polypropylene, polycarbonate, nylon), but also thermosets, elastomers, and even metals (metal injection molding, MIM) or ceramics.

Advantages:

A.Extremely high production speed (thousands to millions of parts)

B.Excellent repeatability and tight tolerances (±0.01 mm possible)

C.Ability to make complex geometries, undercuts, threads, etc.

D.Minimal post-processing needed

E.Wide range of materials and colors

Disadvantages:

A.Very high initial tooling cost (molds can cost $10,000–$200,000+)

B.Long lead time to design and manufacture the mold

C.Not economical for low-volume production (usually < ~1,000 parts)

D.Part design restrictions (draft angles, uniform wall thickness, etc.)

Common Applications:

A.Consumer products: phone cases, toys (LEGO bricks), bottles caps, containers

B.Automotive: dashboards, bumpers, interior trim

C.Medical: syringes, housings for devices

D.Electronics: connectors, enclosures

E.Almost any plastic part you touch daily was likely injection molded

What is Insert Molding?

Insert molding is a specialized type of injection molding where a pre-formed part (called an insert) is placed into the mold, and plastic is injected around it so that the insert becomes a permanent, integrated part of the finished component.It is a single-step process that combines metal, plastic, ceramic, or even another plastic part with newly molded plastic — eliminating the need for secondary assembly operations like press-fitting, gluing, or ultrasonic welding.

How Insert Molding Works (Step-by-Step)

1.Insert preparation – Metal stamps, threaded bushings, pins, electrical contacts, magnets, circuit boards, etc., are manufactured or purchased.

2.Insert loading – Inserts are placed into the mold cavity, either manually or automatically (robots are common in high-volume production).

3.Mold closes – The mold halves close and securely hold the insert in the exact position.

4.Plastic injection – Molten plastic is injected and flows around and into features of the insert.

5.Cooling & solidification – Plastic shrinks slightly as it cools, creating a tight mechanical lock around the insert.

6.Ejection – The finished part (now plastic + insert bonded together) is ejected.

Common Types of Inserts

1.Threaded metal bushings or nuts (eliminates tapping plastic)

2.Metal pins, blades, or contacts (electrical connectors)

3.PCBs or flex circuits (smart sensors, LED housings)

4.Magnets

5.Shafts or bearings

6.Tubes or filters

7.Another plastic part (for multi-material designs)

Advantages of Insert Molding

1.Stronger than press-fit or glued assemblies (plastic mechanically locks onto knurls, holes, or undercuts)

2.Reduces assembly labor and cost (one operation instead of two or more)

3.Improves reliability (no loosening over time)

4.Smaller and lighter final parts (no separate fasteners)

5.Better sealing/waterproofing (plastic flows into grooves)

6.High repeatability in mass production

Disadvantages

1.Higher upfront mold cost (mold must have features to locate and hold inserts precisely)

2.Inserts must withstand injection pressure and temperature

3.Slower cycle time if inserts are loaded manually

4.Scrap rate can increase if inserts are misplaced

Everyday Examples of Insert-Molded Parts

1.Electrical connectors with metal pins molded into plastic housing

2.Screwdriver or power-tool handles with metal shafts

3.Automotive sensors (metal terminals molded into plastic body)

4.Medical devices (metal needles or contacts in plastic hubs)

5.USB sticks or charging ports

6.Knobs with metal threaded inserts

What is Overmolding?

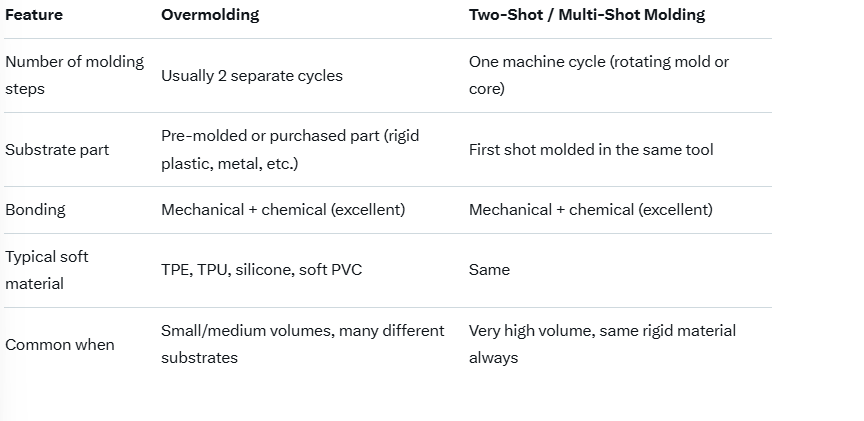

Overmolding is an injection molding process where a second material (usually a soft or rubber-like plastic) is molded directly over a first material (usually a rigid plastic part or a metal/component) to create a single, integrated part with multiple materials, colors, or textures.It is a type of multi-material injection molding — very similar to two-shot molding, but the key difference is in execution and application.

How Overmolding Works (Most Common Method)

1.First part (substrate) is injection-molded separately (or bought as a metal/plastic component).Examples: rigid ABS phone frame, metal wrench handle, polycarbonate housing.

2.Substrate is placed into a second mold (manually or by robot).

3.Second material (soft TPE/TPU) is injected over and around the substrate.

4.The soft material flows into undercuts, grooves, or holes in the substrate → creates a strong mechanical lock.

5.Part cools and is ejected → finished two-material product in one piece.

Advantages of Overmolding

1.Soft-touch or ergonomic feel

2.Better grip (non-slip even when wet)

3.Noise/vibration dampening

4.Waterproof sealing (O-rings molded in place)

5.Improved aesthetics (multi-color, branded logos)

6.Eliminates assembly steps and adhesives

7.Extremely durable bond (almost impossible to peel off)

Disadvantages

1.Higher cost than single-material molding

2.Two molds needed (or one mold + separate first-shot tool)

3.Slower cycle time (especially if manual insert loading)

4.Material compatibility is critical (poor adhesion = delamination)

Everyday Examples You’ve Definitely Held

1.Electric toothbrush (hard body + soft rubber grip areas)

2.Game controllers (hard plastic shell + rubberized thumb grips)

3.Over-ear headphones (hard headband + soft ear cushions)

4.Many kitchen tools (hard core + soft-grip handles)

5.Shaving razors (rigid handle + soft rubber sections)