Die casting is widely used in the production of automotive parts, electronics housings, hardware, and various other industrial and consumer products.

Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity.

- Home

- Capabilities

- Die Casting

What is Die Casting?

Die casting is a metal casting process in which molten metal is forced under high pressure into a reusable steel mold (called a die) to produce precise, high-volume metal parts with excellent surface finish and dimensional accuracy.

Key Characteristics

1.Pressure: Typically 1,000–30,000 psi (much higher than gravity or low-pressure casting)

2.Materials: Almost always non-ferrous alloys (cannot use steel/iron because they would melt the steel die)Most common: Aluminum, Zinc, Magnesium, some Copper alloys

3.Cycle time: Very fast — seconds to a minute per shot

4.Part complexity: Excellent for thin walls, fine details, and complex geometries

5.Tooling cost: High (steel dies cost $20,000–$250,000+)

6.Per-part cost: Very low in high volumes (thousands to millions of parts)

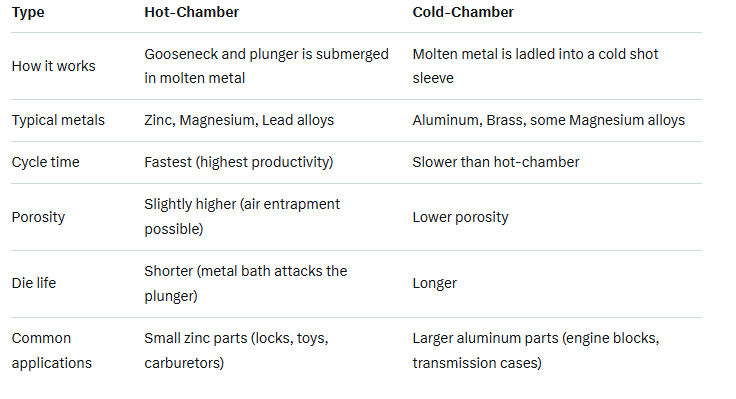

Two Main Types of Die Casting

The Die Casting Process Step-by-Step

1.Die is closed and clamped with enormous force (hundreds to thousands of tons).

2.Molten metal is injected at high velocity (30–100+ m/s) into the die cavity.

3.Metal solidifies rapidly (seconds) due to the cold steel die.

4.Die opens and part is ejected (often with ejector pins).

5.Trim die or robot removes runner, overflows, and flash.

6.Cycle repeats — modern machines can produce a part every 10–60 seconds.

Advantages

1.Extremely high production rates

2.Excellent dimensional accuracy and surface finish (often no machining needed)

3.Thin walls possible (1–2 mm for zinc, 2–4 mm for aluminum)

4.Long die life (100,000–1,000,000+ shots for zinc, 50,000–200,000 for aluminum)

Disadvantages

1.High initial tooling cost

2.Limited to non-ferrous metals

3.Trapped air can cause porosity (mitigated by vacuum die casting or pore-free processes)

4.Part size limited by machine clamping force (largest machines ~4,500 tons)

Common Applications

1.Automotive: transmission cases, engine blocks, wheels, brackets

2.Consumer electronics: laptop and phone bodies, heat sinks

3.Appliances: washer/dryer parts, power tool housings

4.Hardware: locks, faucets, door handles (mostly zinc)

In short, die casting is the go-to process when you need tens of thousands to millions of precise, thin-walled metal parts at the lowest possible per-piece cost.

Aluminum alloy high-pressure die casting is an important manufacturing process known for its superior performance and wide range of applications. Selecting the appropriate high-pressure die casting technique can effectively enhance product quality and production efficiency.

Characteristics of Aluminum Alloy High-Pressure Die Casting

High Precision and Complex Shapes

High-pressure die casting allows for the production of intricate geometries with high dimensional accuracy and smooth surface finishes.

Excellent Mechanical Properties

Aluminum alloys used in this process exhibit good strength and rigidity, making them suitable for high-load and high-pressure applications.

Rapid Production

This method has a short production cycle, making it ideal for high-volume manufacturing and significantly increasing production efficiency.

Good Surface Quality

The die-cast aluminum parts typically have a smooth surface, reducing the need for extensive post-processing.

Lightweight

Aluminum alloys have a low density, resulting in lightweight components that help reduce the overall weight of structures.

Corrosion Resistance

Aluminum alloys possess excellent corrosion resistance, making them suitable for various environmental conditions.

Applications of Aluminum Alloy High-Pressure Die Casting

Automotive Industry

Used to manufacture engine components, transmission housings, and structural parts, helping to reduce vehicle weight and improve fuel efficiency.

Electronics

Employed in producing enclosures and internal components for electronic devices, such as mobile phones and computer casings, providing good heat dissipation.

Aerospace

Utilized in the production of lightweight aircraft components, such as fuselage frames and engine parts, meeting stringent strength and weight requirements.

Household Appliances

Used to manufacture parts for appliances, such as air conditioners and refrigerators, enhancing durability and aesthetics.

Industrial Equipment

Applied in producing various mechanical and equipment components, offering high strength and wear resistance solutions.

The counterpart of aluminum alloy die casting is zinc alloy die casting.

Zinc alloy has high density and is suitable for forging surface treatment, which looks high-end and atmospheric.

Zinc alloy die casting is an essential manufacturing process recognized for its diverse applications and notable advantages. Choosing zinc alloy die casting can effectively enhance product quality and meet market demands.

Applications of Zinc Alloy Die Casting

Automotive Industry

Used for manufacturing various automotive components such as light housings, door locks, and dashboard parts, enhancing vehicle performance and safety due to its lightweight properties.

Electronics

Employed in producing enclosures and internal components for electronic devices, including mobile phone casings and computer housings, providing excellent heat dissipation and protection.

Household Appliances

Utilized in producing parts for household appliances like washing machines and refrigerators, improving durability and aesthetic appeal.

Toys and Consumer Products

Used to manufacture components for various toys and consumer products, as it allows for easy shaping and surface finishing, making it suitable for mass production.

Construction and Decoration

Applied in producing hardware for doors and windows, lighting fixtures, and other decorative components, enhancing both functionality and appearance.

Advantages of Zinc Alloy Die Casting

Excellent Mechanical Properties

Zinc alloys offer good strength and rigidity, making them suitable for applications that require load-bearing capabilities.

Precision Casting

The die casting process allows for high precision and complex shapes, reducing the need for extensive post-processing.

Good Surface Quality

Zinc alloy die-cast parts typically have smooth surfaces, making them easier to finish with coatings such as painting or plating.

Rapid Production

This method is ideal for high-volume production, significantly increasing manufacturing efficiency and reducing costs.

Recyclability

Zinc alloys can be recycled, aligning with sustainable development goals and minimizing resource waste.

Corrosion Resistance

Zinc alloys exhibit good corrosion resistance, making them suitable for various environmental conditions and extending the lifespan of products.

Zinc alloy die casting is an essential manufacturing process recognized for its diverse applications and notable advantages. Choosing zinc alloy die casting can effectively enhance product quality and meet market demands.