Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is zinc die-cast material?

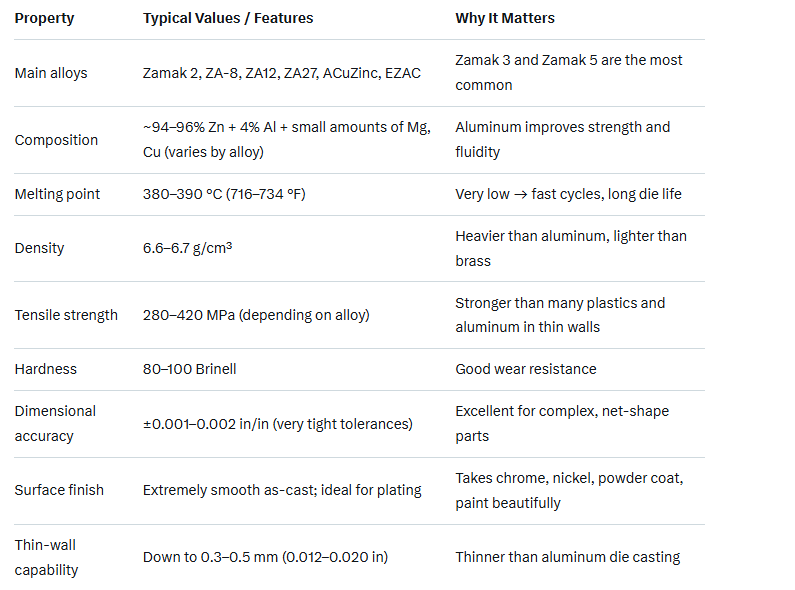

Zinc die-cast material (also called zinc die-casting alloy or simply zinc alloy) is a family of precision-cast metals made by injecting molten zinc under high pressure into a steel mold (die). It is one of the most popular die-casting metals alongside aluminum and magnesium.

Key Characteristics

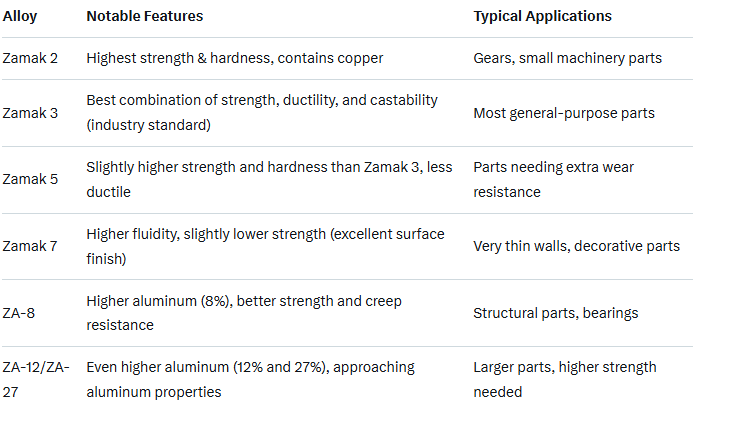

Most Common Zinc Die-Casting Alloys

Advantages of Zinc Die Casting

A.Exceptional dimensional accuracy and stability (parts often need no secondary machining)

B.Very smooth surface → perfect for electroplating (chrome bathroom fittings, automotive trim, etc.)

C.Fast production cycles (zinc solidifies quickly)

D.Thin walls and complex geometries possible

E.Excellent EMI/RFI shielding (used in electronics housings)

F.100% recyclable

Disadvantages vs. Other Die-Cast Metals

A.Heavier than aluminum or magnesium

B.Lower maximum operating temperature (~120 °C continuous before creep becomes an issue)

C.Slightly more expensive raw material cost than aluminum (but often offset by longer die life and faster cycles)

Typical Applications

A.Automotive: door handles, lock components, carburetor bodies, seat-belt parts

B.Electronics: connector housings, shields, heat sinks

C.Consumer goods: bathroom faucets, zippers, toys, power-tool housings

D.Locks and hardware: keys, lock bodies, hinges

E.Appliances: knobs, decorative trim

In short, when a part needs tight tolerances, excellent surface finish for plating, thin walls, and high production volumes, zinc die-cast material is usually the go-to choice.