Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is die cast zinc strong?

Yes, die-cast zinc (typically alloys like Zamak 3, Zamak 5, or ZA-8) is reasonably strong for many applications, but its strength depends on context and what you compare it to.

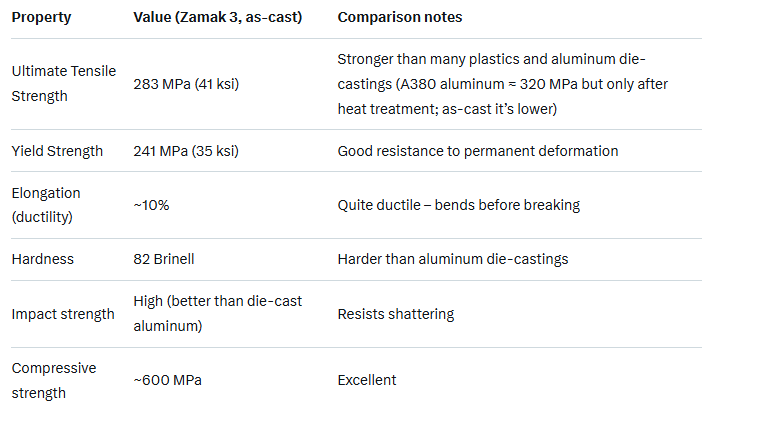

Here are typical mechanical properties for the most common die-cast zinc alloy (Zamak 3):

How strong is it in practical terms?

A.Stronger and harder than die-cast aluminum in most cases (especially impact resistance and wear).

B.Much stronger than plastics or pot metal (old low-grade zinc alloys).

C.Weaker than steel, brass, or heat-treated aluminum alloys.

D.Comparable to or slightly stronger than 6061-T6 aluminum in tension, but zinc is denser (6.6 g/cm³ vs 2.7 g/cm³ for Al).

Common uses that prove its strength

A.Automotive: door lock housings, seat belt parts, carburetor bodies (pre-EFI)

B.Tools: bodies of padlocks, good-quality hand tools, tape measures

D.Electronics: connector housings, shield cans

C.Firearms: some pistol frames (Hi-Point, some Ruger .22s) are Zamak and survive tens of thousands of rounds

Limitations

A.Creeps (slowly deforms) under sustained high loads above ~100°C.

B.Loses strength rapidly above 120–150°C (so not good for very hot environments).

C.Heavier than aluminum or magnesium.

Bottom line

For a die-cast material, zinc is one of the strongest and toughest options available, especially when you factor in impact resistance, wear resistance, and dimensional stability. It’s plenty strong for small structural parts, housings, locks, gears, etc., which is why it’s been the go-to material for high-quality pot-metal parts for decades. If you need something stronger/lighter and can tolerate higher cost, you’d step up to machined steel, forged aluminum, or investment-cast stainless.