Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is die casting?

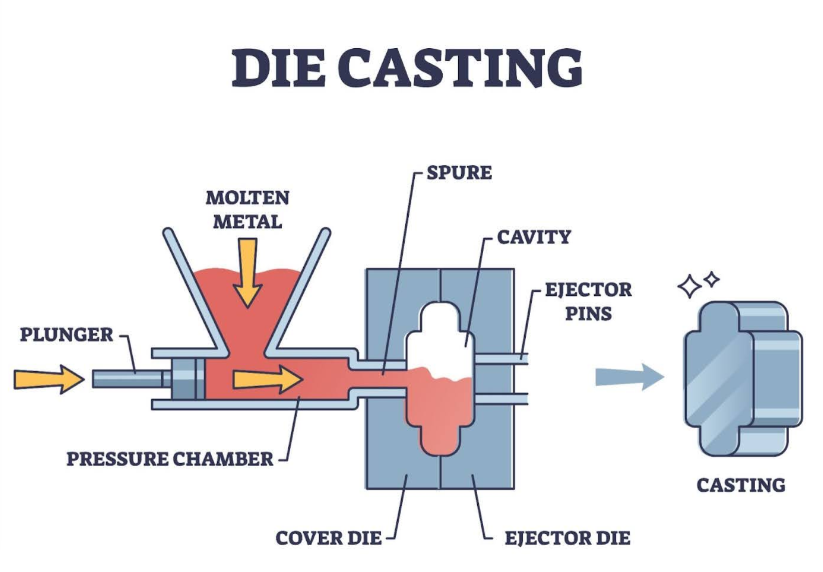

Die casting is a metal casting process that involves forcing molten metal under high pressure into a reusable steel mold (called a die) to produce precise, complex parts with smooth surfaces and tight tolerances.This method is similar to injection molding but uses metals instead of plastics, making it ideal for high-volume production of detailed components.

The Basic Process

1.The two halves of the die are clamped together and prepared with lubricant.

2.Molten metal is injected into the die cavity at high pressure (typically 10–140 MPa).

3.The metal solidifies rapidly under pressure.

4.The die opens, and the part is ejected.

5.Excess material is trimmed, and the part may undergo finishing.

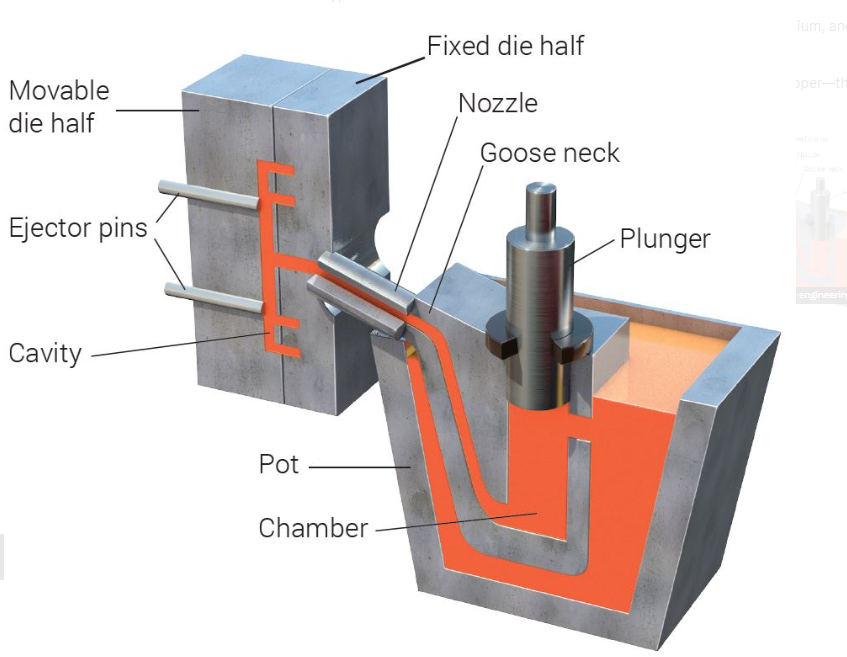

There are two main types:

1.Hot-chamber die casting: Faster, used for lower-melting-point metals like zinc, magnesium, and lead—the injection mechanism is immersed in molten metal.

2.Cold-chamber die casting: Used for higher-melting-point metals like aluminum and copper—the molten metal is ladled into the chamber separately.

Common Materials

1.Primarily non-ferrous alloys:Aluminum (lightweight, corrosion-resistant, strong).

2.Zinc (easy to cast, high ductility, economical for small parts).

3.Magnesium (lightest structural metal).

4.Copper, lead, or tin-based alloys for specific needs.

Advantages

1.High dimensional accuracy and smooth finishes, often requiring little post-machining.

2.Excellent for complex, thin-walled geometries.

3.Fast production rates and low per-part cost in high volumes.

4.Good mechanical properties like strength and ductility.

Applications

Widely used in automotive (engine blocks, transmission cases, wheels), consumer electronics, appliances, aerospace, and toys (e.g., Hot Wheels cars).