Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Why are zinc alloys used for die casting?

Zinc alloys are widely used in die casting due to their unique combination of material properties, process advantages, and cost-effectiveness, making them ideal for high-volume production of precise, durable parts.

Key Reasons and Benefits

1.Low Melting Point (420°C): This enables the efficient hot-chamber die casting process, where the injection mechanism is submerged in molten metal for faster cycle times compared to cold-chamber processes required for higher-melting alloys like aluminum (660°C) or magnesium. Faster cycles boost productivity and reduce energy costs.

2.Excellent Fluidity and Castability: Molten zinc flows easily, allowing it to fill intricate molds with thin walls (as low as 0.5-1 mm), complex geometries, tight tolerances, and smooth surfaces. This minimizes the need for secondary machining and enables near-net-shape parts.

3.Superior Mechanical Properties: Zinc alloys (e.g., Zamak series like Zamak 3, 5, 7; ZA alloys like ZA-8, ZA-27) offer high strength, hardness, impact resistance, ductility, and creep resistance—often exceeding aluminum or magnesium in tensile/yield strength and elongation while maintaining rigidity. They also provide good bearing/wear properties, vibration dampening, and EMI/RFI shielding.

4.Long Tool Life and Low Wear: The lower melting temperature and less abrasive nature of zinc result in dies lasting up to 10 times longer than those for aluminum, significantly reducing tooling costs over high-volume runs.

5.Superior Finishing and Aesthetics: Cast parts have smooth surfaces suitable for plating (e.g., chrome, nickel), painting, or powder coating, providing excellent corrosion resistance and decorative appeal.

6.Cost-Effectiveness: Lower material and processing costs, high production rates, recyclability (zinc is highly recyclable with low energy input), and minimal waste make it economical, especially for small-to-medium-sized parts.

7.Other Advantages: Good thermal/electrical conductivity, non-sparking (for safety), and environmental benefits from reduced energy use.

These properties make zinc die casting particularly popular in automotive (e.g., door handles, locks, gears), electronics (housings, connectors), hardware, and consumer goods.

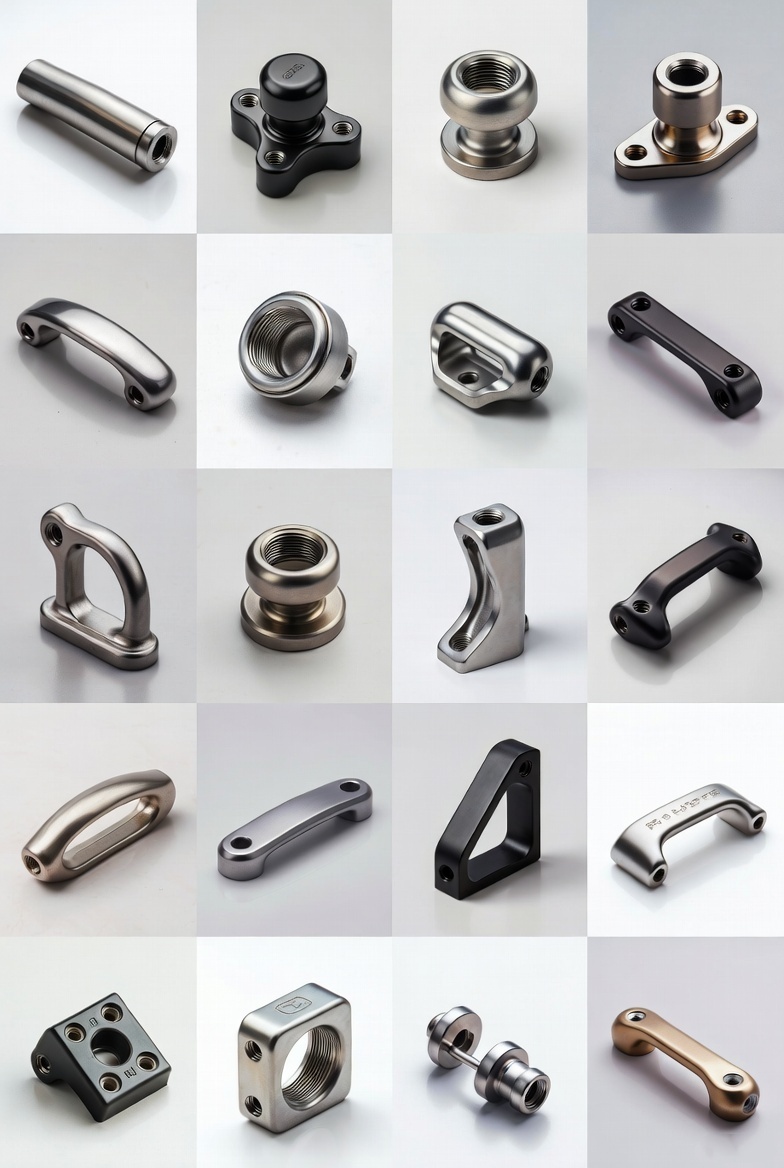

Here are some examples of zinc die cast parts: