Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to cast metal 3d printed part prototype?

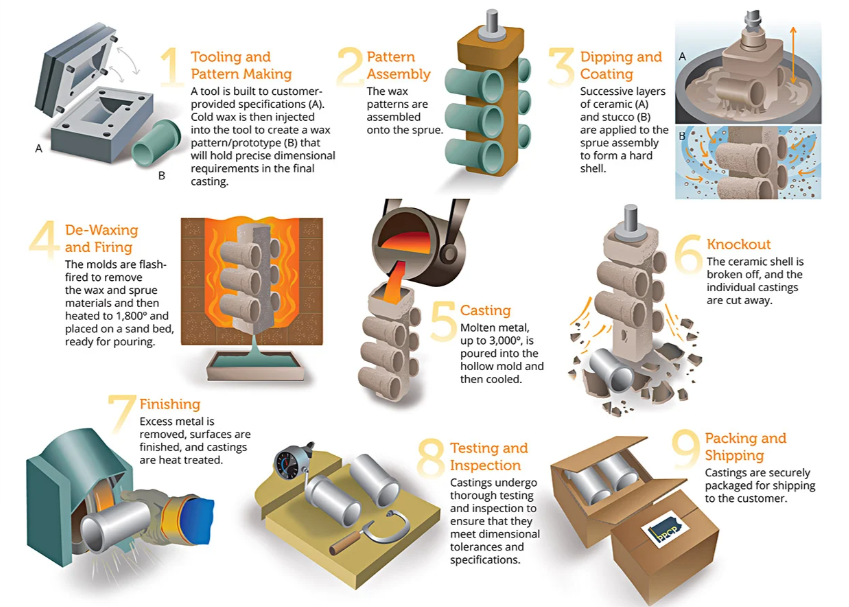

The most common and effective way to create a cast metal prototype from a 3D printed part is through investment casting (also known as lost-wax or lost-polymer casting). This uses the 3D printed part as a sacrificial pattern that is "lost" (burned or melted out) during the process, leaving a mold for pouring molten metal.

This method is widely used for prototyping because it allows complex geometries, fine details, and quick iterations without expensive tooling. It's suitable for metals like aluminum, bronze, brass, steel, or even precious metals.

Key Methods Overview

There are two primary approaches depending on your 3D printing technology:

1.Direct Pattern (Most Common for Prototyping):

Print the positive pattern directly using castable resin (SLA/DLP printers) or special castable/wax-like filaments (FDM printers).Ideal for high detail and smooth surfaces.The direct method is faster for one-offs/prototypes.

2.Indirect (Master Pattern for Molds):

Print a master in standard material (e.g., PLA or resin).Use it to create a reusable silicone mold, then inject wax or low-melt alloy for patterns.Better for multiples or low-temperature metals (e.g., bismuth alloys).

Step-by-Step Process for Direct Investment Casting

1.Design the Model:

2.3D Print the Pattern:

3.Build the Investment (Ceramic Shell):

4.Burnout the Pattern:

5.Pour the Metal:

6.Finish the Casting:

Tips for Success

1.Safety First — Work with high heat, molten metal, and fumes — use PPE, ventilation, and proper equipment.

2.Material Choice — Castable resins give the best detail and clean burnout. Test burnout on scraps.

3.Common Issues — Incomplete burnout causes cracks/ash defects; poor gating leads to air pockets.

4.Alternatives:For simple/large parts: Sand casting with a printed pattern (pack sand around it, remove/burn out).For very low-melt metals: Direct pour into heat-resistant printed molds (rare, limited metals).

5.Professional Services — For best results or complex parts, send patterns to a foundry (many accept 3D printed files/patterns).

This process can yield prototypes in days at low cost compared to direct metal 3D printing. Start small to test your setup!