Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to make smooth prototype for molding making and casting?

Creating a Smooth Prototype for Mold Making and Casting

A smooth prototype (often called the "master" or "original") is essential for producing high-quality molds and casts. Any imperfections on the prototype, such as rough surfaces, layer lines, or pores, will transfer to the mold and subsequent casts. The goal is to achieve a polished, sealed surface that allows for easy release and captures fine details. Below, I'll outline common methods to create and smooth prototypes, drawing from standard practices in crafting, 3D printing, and manufacturing. These are suitable for materials like resin, silicone, or metal casting.

Step 1: Choose Your Prototype Creation Method

1.Sculpting by Hand: Use modeling clay (e.g., polymer clay like Sculpey), wax, or foam. These are ideal for organic shapes. Sculpt with tools like loops, ribs, or spatulas for initial smoothness.

2.3D Printing: Popular for precise, complex designs. Use filaments like PLA, ABS, or resin-based prints (e.g., via SLA printers) for better initial surface quality. Design in software like Fusion 360 or Blender, ensuring minimal undercuts for easier molding.

3.Machining or Carving: For rigid materials like wood, machinable wax, or foamed PVC. CNC milling provides clean edges but may require post-processing for smoothness.

4.Other Options: For metal prototypes, consider sand casting or 3D printing as starting points, then refine.

Step 2: Basic Preparation

1.Fix the prototype to a stable base (e.g., MDF board or foamed PVC) with glue to prevent movement during molding.

2.If the prototype has undercuts or complex geometry, plan for a two-part mold by adding a parting line (e.g., with clay).

3.Measure the prototype's volume (e.g., with water displacement or rice) to calculate mold material needs.

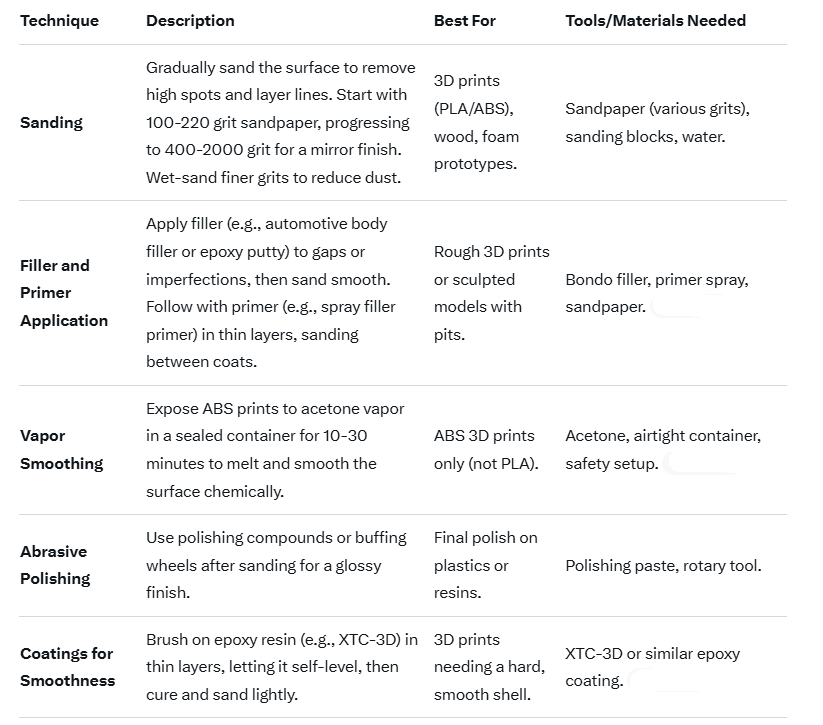

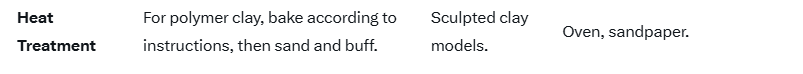

Step 3: Smoothing Techniques

Tips for Success: Always smooth the master prototype thoroughly, as this directly affects mold quality. Test small areas first. For porous materials (e.g., wood or natural clay), seal with varnish, PVA glue, or shellac to prevent mold material absorption and ensure a clean release. Apply a thin layer of release agent like Vaseline to detailed areas, but avoid excess to preserve texture.

Step 4: Verify Smoothness and Proceed to Molding

1.Inspect under light for imperfections; the surface should feel glass-like.

2.Build a containment box around the prototype (e.g., with cardboard or clay walls) to hold the mold material.

3.For molding: Use silicone rubber (e.g., Smooth-Sil 960) for flexible molds.

4.Brush a thin detail coat first, then pour the rest. Cure for 24 hours.

For casting: Mix materials like polyurethane resin (e.g., Smooth-Cast 305) in equal parts, pour into the mold, and demold after setting.

5.Tap to release bubbles.

Additional Considerations

1.For 3D Printed Prototypes: Simplify designs in CAD to reduce post-processing; use high-resolution settings for fewer layer lines.

2.Cost and Speed: Hand sculpting is cheap but time-intensive; 3D printing is faster for iterations.

3.Safety: Wear PPE; some materials (e.g., resins) release fumes.

4.If scaling up, consider professional techniques like investment casting for smoother metal prototypes.