Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to vacuum cast?

What is Vacuum Casting?

Vacuum casting (also known as urethane casting or silicone molding) is a prototyping and low-volume production technique used to create high-quality plastic parts. It involves making a silicone mold from a master pattern (often 3D-printed), then pouring polyurethane resin into the mold under vacuum to eliminate air bubbles, resulting in detailed, bubble-free replicas. It's ideal for 10–50 parts per mold and mimics properties of injection-molded plastics like ABS, PC, or PP.

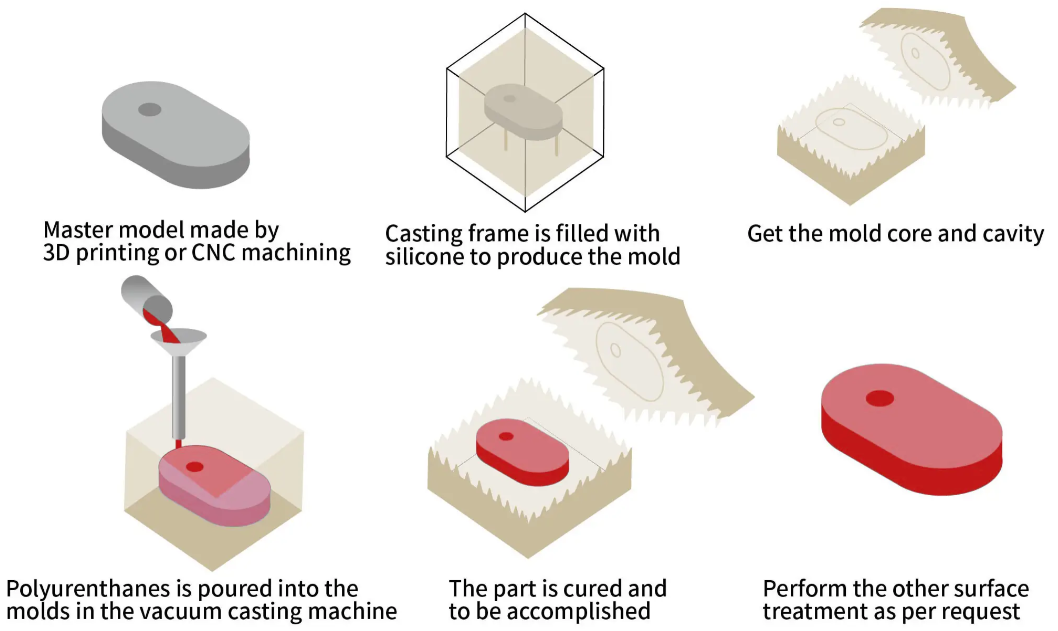

Step-by-Step Guide to Vacuum Casting

1.Create a Master Pattern

Start with a high-quality master model of your part. This is typically 3D printed (e.g., SLA for fine details) or CNC machined. Finish it by sanding, polishing, and applying a release agent to ensure smooth removal later.

2.Build the Mold Box and Suspend the Master

Place the master in a mold box. Add gating systems (sprues, vents, risers) using clay or acrylic rods for resin flow and air escape. Suspend it properly to avoid undercuts issues.

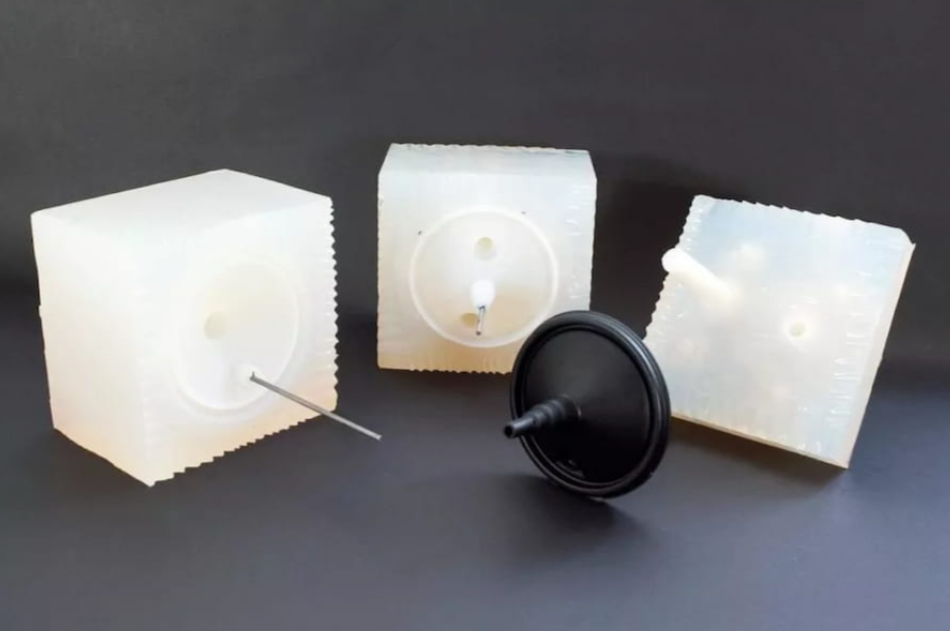

3.Pour and Cure the Silicone Mold

Mix liquid silicone rubber and pour it over the master in the box. Degass the silicone under vacuum if needed to remove bubbles. Cure in an oven (typically 40–80°C for several hours). Once cured, cut the mold along a parting line, remove the master, and apply mold release agent.

4.Prepare the Resin

Choose a polyurethane (PU) resin that matches desired properties (e.g., rigid like ABS, flexible like rubber, transparent like PC). Preheat to ~40°C for better flow. Mix the two-part resin (A + B) thoroughly, add pigments if needed, and degas under vacuum for 50–60 seconds to remove air.

5.Pour Resin into the Mold Under Vacuum

Place the reassembled silicone mold in a vacuum chamber. Pour the mixed resin into the mold while applying vacuum—this draws the resin into fine details and prevents bubbles. Some setups use automatic mixing/pouring machines.

6.Cure the Part

Cure the filled mold in an oven (typically 60–80°C for 1–2 hours, depending on resin). Release vacuum if needed during curing.

7.Demold and Finish

Open the mold, remove the part. Trim gates/vents, sand, paint, or add finishes (e.g., clear coat for transparency). One silicone mold can produce 10–50 parts before degrading.

Equipment Needed

Vacuum chamber and pump (commercial or DIY setups possible).

Oven for curing.

Mixing tools, scales, and safety gear (gloves, respirator—resins can be toxic).