Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is vacuum permanent-mold casting

Vacuum permanent-mold casting (also known as vacuum permanent mold casting or VPMC) is a variation of the permanent mold casting process. It uses a reusable metal mold (typically steel or cast iron) and applies vacuum pressure to draw molten metal into the mold cavity, improving casting quality compared to gravity-fed methods.

How It Differs from Standard Permanent Mold Casting

Standard permanent mold casting relies on gravity (or sometimes low pressure) to fill the mold. Vacuum permanent-mold casting creates negative pressure in the mold cavity, which pulls the molten metal upward through risers or gating systems. This reduces turbulence, minimizes air entrapment, and degasses the metal.

The Process

1.The permanent mold is preheated and coated with a refractory material to prevent sticking and extend mold life.

2.The mold is sealed or placed in a vacuum chamber.

3.A vacuum is applied to evacuate air from the cavity.

4.Molten metal (commonly non-ferrous alloys like aluminum or magnesium) is drawn into the mold by the negative pressure.

5.The metal solidifies under controlled conditions, often with the vacuum maintained to aid feeding and reduce shrinkage.

6.The mold is opened, and the casting is ejected.

This method is similar to low-pressure permanent mold casting (which pushes metal with gas pressure) but uses suction instead, often resulting in even lower porosity.

Advantages

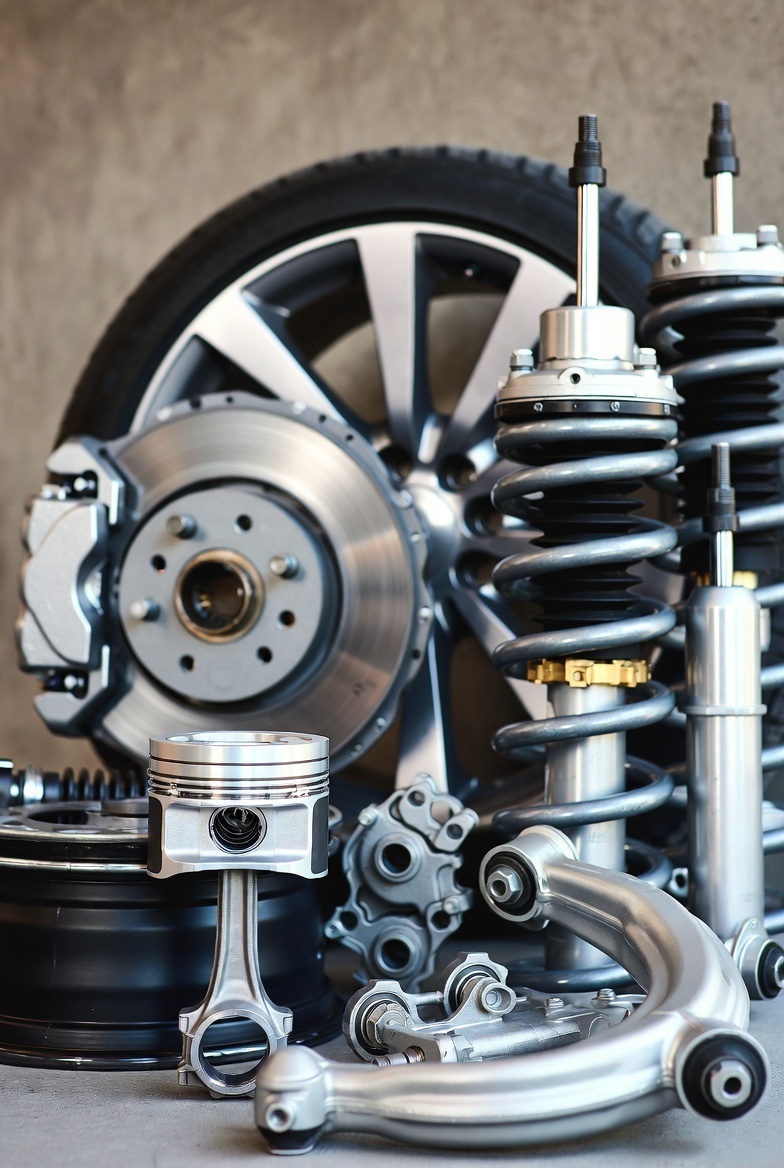

1.Exceptionally low porosity and gas defects due to vacuum degassing.

2.Higher density, better mechanical properties, and superior strength.

3.Excellent surface finish and dimensional accuracy.

4.Suitable for thin-walled, complex, or high-integrity parts.

5.Reduced oxidation and inclusions.

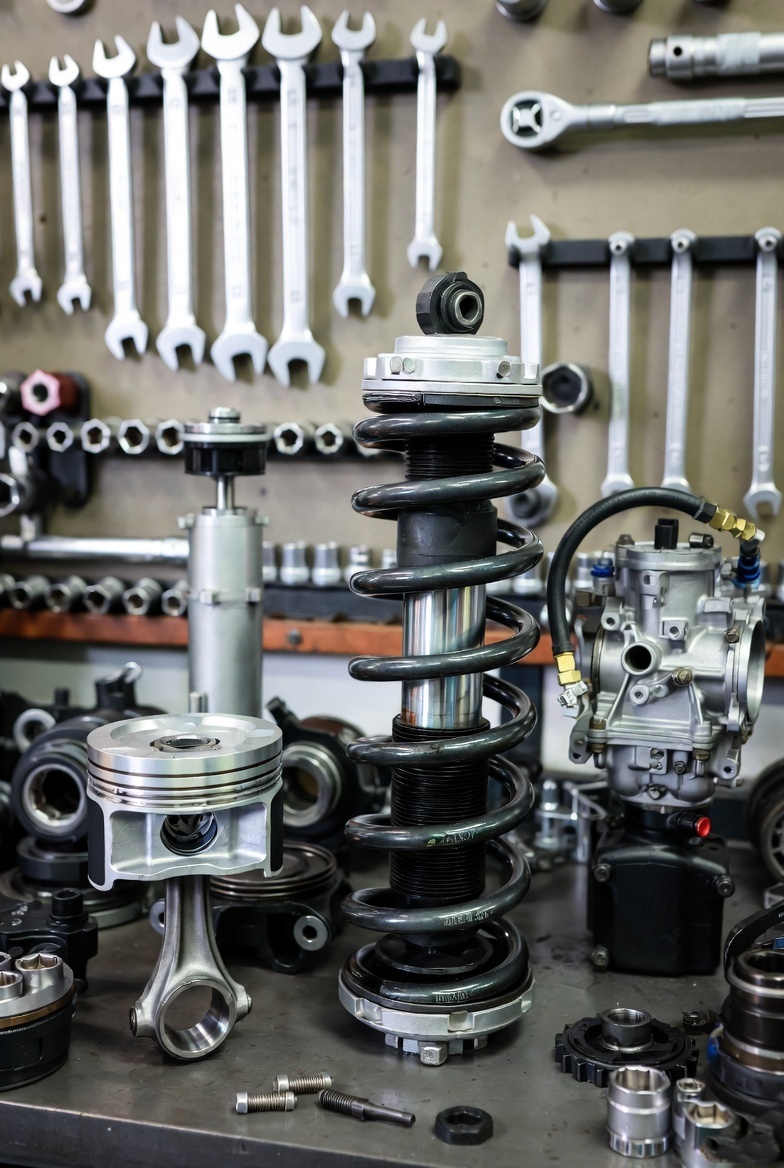

Applications

It is commonly used in automotive (e.g., pistons, suspensions), aerospace, and high-performance components requiring minimal defects.