Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is engineering prototype services?

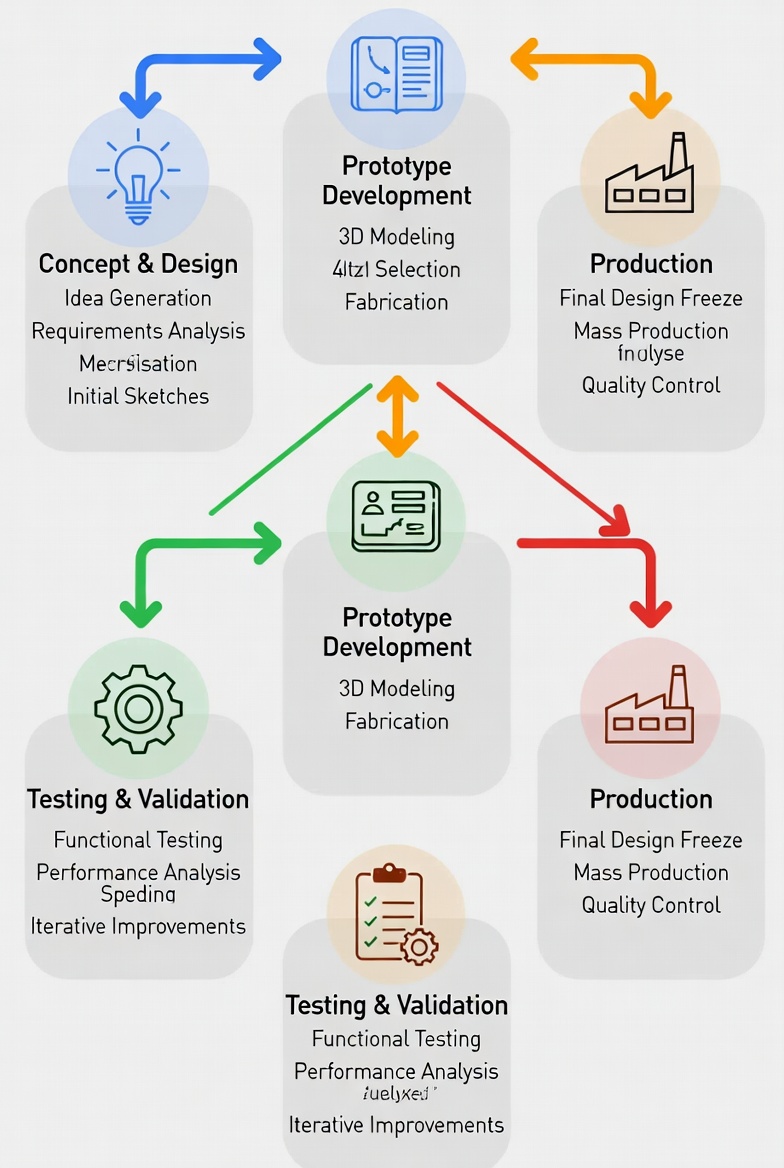

Engineering prototype services are professional offerings provided by specialized companies or engineering firms to help inventors, startups, and businesses transform product ideas into tangible prototypes. These services bridge the gap between conceptual design and full-scale manufacturing by creating early versions of a product for testing, validation, and refinement.

What They Involve

These services typically include:

1.Design and engineering support — Refining CAD models, ensuring technical feasibility, and optimizing for functionality and manufacturability.

2.Fabrication of prototypes — Using various methods to build physical models.

3.Testing and iteration — Evaluating performance, gathering feedback, and making improvements.

4.Transition to production — Preparing designs for low-volume or mass manufacturing.

Common fabrication techniques

1.include:Rapid prototyping (e.g., 3D printing/additive manufacturing for quick, cost-effective parts).

2.CNC machining for precise metal or plastic components.

3.Injection molding or vacuum casting for higher-fidelity models.

4.Sheet metal fabrication, laser cutting, or traditional machining.

Prototypes range from low-fidelity (rough mock-ups for concept validation) to high-fidelity (near-production-quality for functional testing).

Why They Matter

The primary goal is to reduce risks by identifying design flaws early, validating user experience, and ensuring the product is viable before committing to expensive tooling or production. This accelerates development, minimizes costs, and improves the final product's quality.Here are some visual examples of engineering prototypes: