Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is Rapid Prototyping in Engineering?

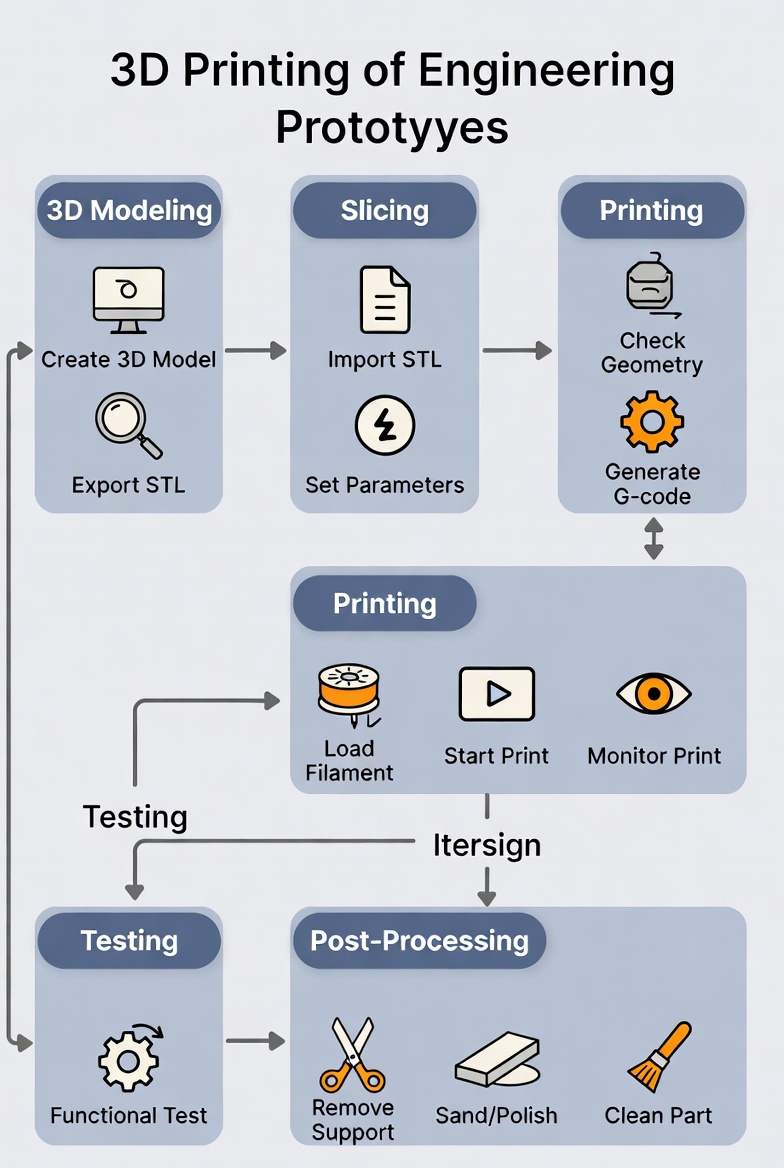

Rapid prototyping (RP) is a group of techniques used to quickly fabricate a physical scale model or functional part from a 3D computer-aided design (CAD) model. It allows engineers to iterate designs rapidly, test concepts, and validate functionality early in the product development process, reducing time and costs compared to traditional methods like machining or molding.Introduced in the late 1980s, RP has evolved with additive manufacturing (commonly known as 3D printing) becoming dominant. It bridges digital design and physical testing, enabling frequent revisions based on real-world feedback.

Common Rapid Prototyping Techniques

Here are the most widely used methods in engineering:

1.Stereolithography (SLA): Uses a laser to cure liquid resin layer by layer. Ideal for high-detail prototypes with smooth finishes, such as patterns or molds.

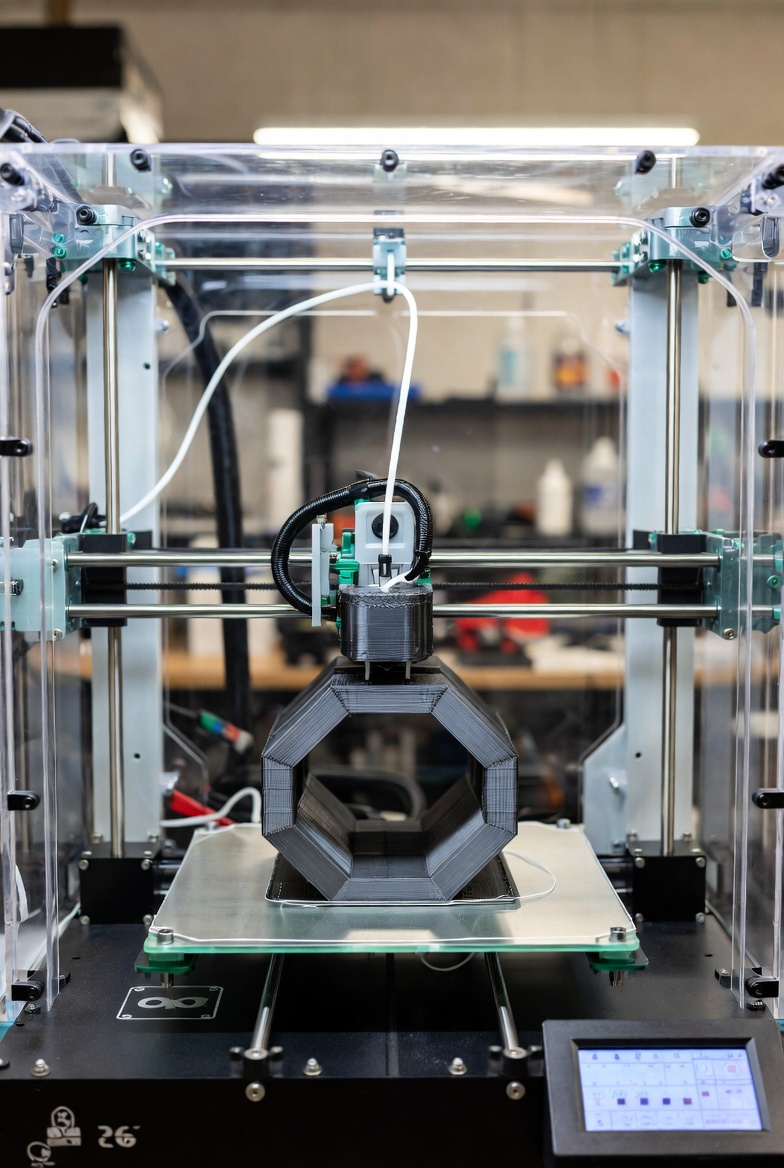

2.Fused Deposition Modeling (FDM/FFF): Extrudes thermoplastic filament through a heated nozzle. Affordable and versatile for conceptual models and functional parts.

3.Selective Laser Sintering (SLS): Fuses powder (plastic, metal, or ceramic) with a laser. Strong for durable prototypes without supports.

4.Selective Laser Melting (SLM/DMLS): Fully melts metal powder for high-strength parts, used in aerospace and automotive.

5.CNC Machining: Subtractive method for precise prototypes from metals or plastics.

6.Other: Binder Jetting, PolyJet (multi-material), and vacuum casting for small batches.

Benefits in Engineering

1.Speed: Prototypes in hours/days vs. weeks.

2.Cost-Effective Iteration: Early flaw detection reduces expensive changes later.

3.Complex Geometries: Internal features or lightweight structures impossible with traditional methods.

4.Customization: Ideal for one-offs or personalized parts.

Risk Reduction: Test form, fit, and function before full production.

Applications

Widely used in aerospace (lightweight components), automotive (engine parts), medical (implants/prosthetics), consumer products, and more.

Trends as of 2025

The market is growing rapidly (projected CAGR ~20%), with advancements in AI-optimized designs, multi-material printing, sustainable materials, and integration with simulation tools. Technologies like high-speed metal printing and hybrid systems are accelerating innovation.Rapid prototyping transforms engineering by enabling faster, more innovative product development.