Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is prototype investment casting?

Prototype investment casting, also known as rapid prototype investment casting or lost-wax casting for prototyping, is a precision manufacturing process used to create functional metal prototypes or low-volume parts quickly and cost-effectively. It adapts the traditional investment casting method (an ancient technique dating back thousands of years) by incorporating modern rapid prototyping technologies, such as 3D printing, to eliminate the need for expensive tooling.

This approach is ideal for design validation, functional testing, and small production runs before committing to full-scale manufacturing. It produces parts with excellent dimensional accuracy, smooth surface finishes, complex geometries (including thin walls and internal features), and material properties matching production castings—often superior to direct 3D metal printing or machined prototypes in cost and performance for low volumes.

Key Advantages

1.Rapid turnaround → often days or weeks instead of months.

2.No hard tooling required → reducing costs for prototypes.

3.Ability to use production-grade alloys → like stainless steel, aluminum, titanium, or superalloys.

4.Suitable for industries like aerospace, automotive, defense, medical, and energy.

The Process

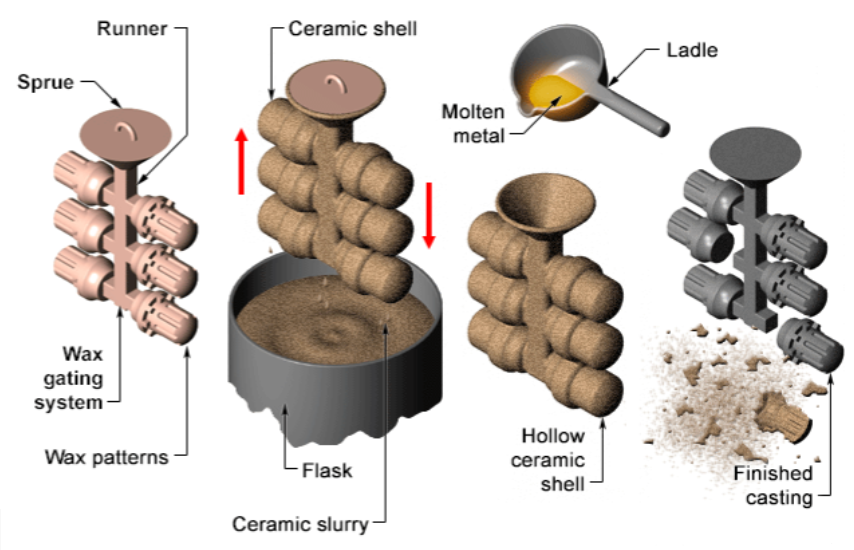

The core steps of prototype investment casting are similar to traditional investment casting but accelerated by using 3D-printed patterns instead of injected wax from metal dies:

1.Pattern Creation: A digital CAD model is used to 3D print a pattern (often in wax, resin, or plastic) directly. This replaces the traditional wax injection tooling step.

2.Assembly (Tree Building): Patterns are attached to a central sprue (gating system) to form a "tree" for efficient casting.

3.Shell Building: The tree is repeatedly dipped in ceramic slurry and coated with refractory material to build a strong ceramic shell mold.

4.Dewax/Burnout: The shell is heated to melt out (or burn off) the pattern, leaving a hollow ceramic mold.

5.Metal Pouring: Molten metal is poured into the preheated shell (often under vacuum or gravity).

6.Shell Removal and Finishing: The shell is broken away, parts are cut from the tree, and post-processing (machining, heat treatment, etc.) is applied as needed.

This method bridges the gap between conceptual design and production, allowing multiple design iterations with minimal risk and expense.