Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to injection mold plastic?

Injection molding is a manufacturing process used to produce plastic parts in high volumes. It involves melting plastic material and injecting it under high pressure into a mold cavity, where it cools and solidifies into the desired shape. This method is ideal for creating complex, precise parts like toys, automotive components, medical devices, and household items.

Key Components

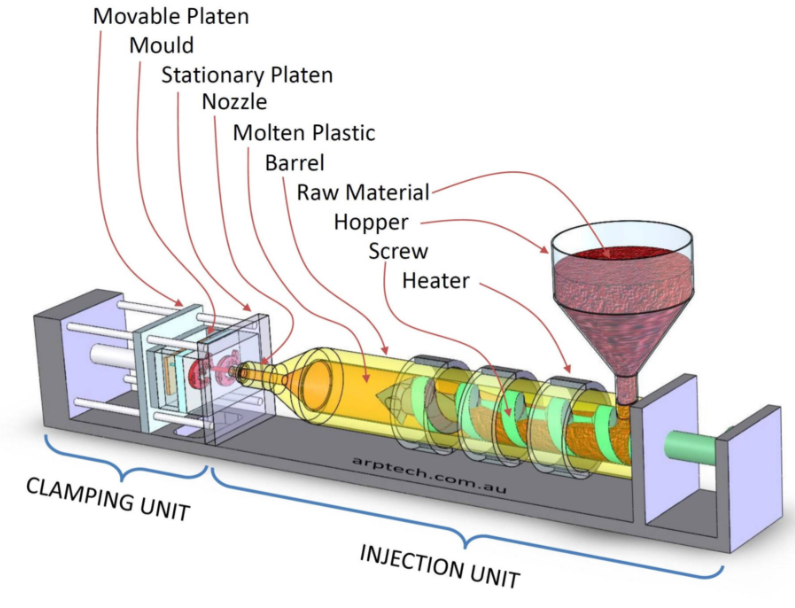

1.Injection Molding Machine: Includes a hopper (for plastic pellets), barrel with heaters, reciprocating screw (to melt and inject), nozzle, and clamping unit.

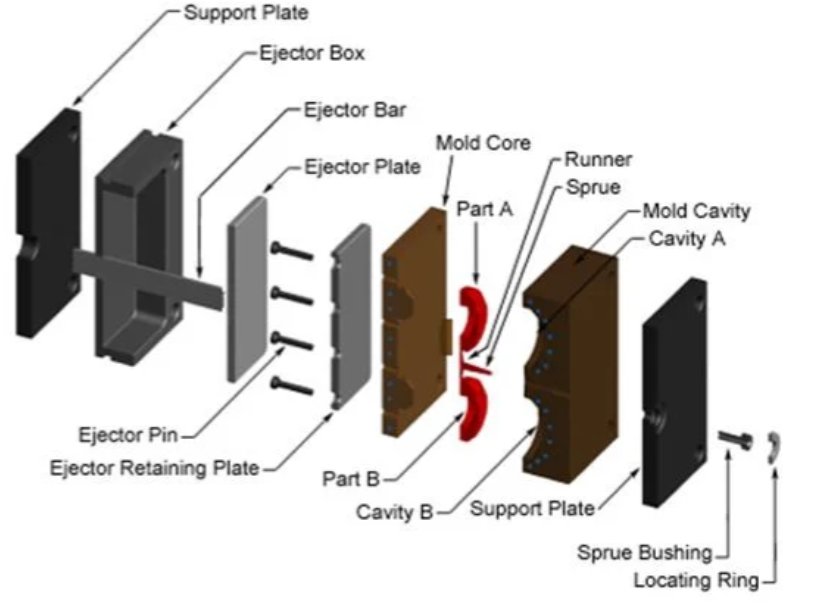

2.Mold: Typically made of steel or aluminum, consisting of two halves (core and cavity), runners, gates, cooling channels, and ejection system.

Here are diagrams illustrating a typical injection molding machine and mold components:

Step-by-Step Process

The injection molding cycle typically takes seconds to minutes, depending on part size and material. Here's the standard sequence:

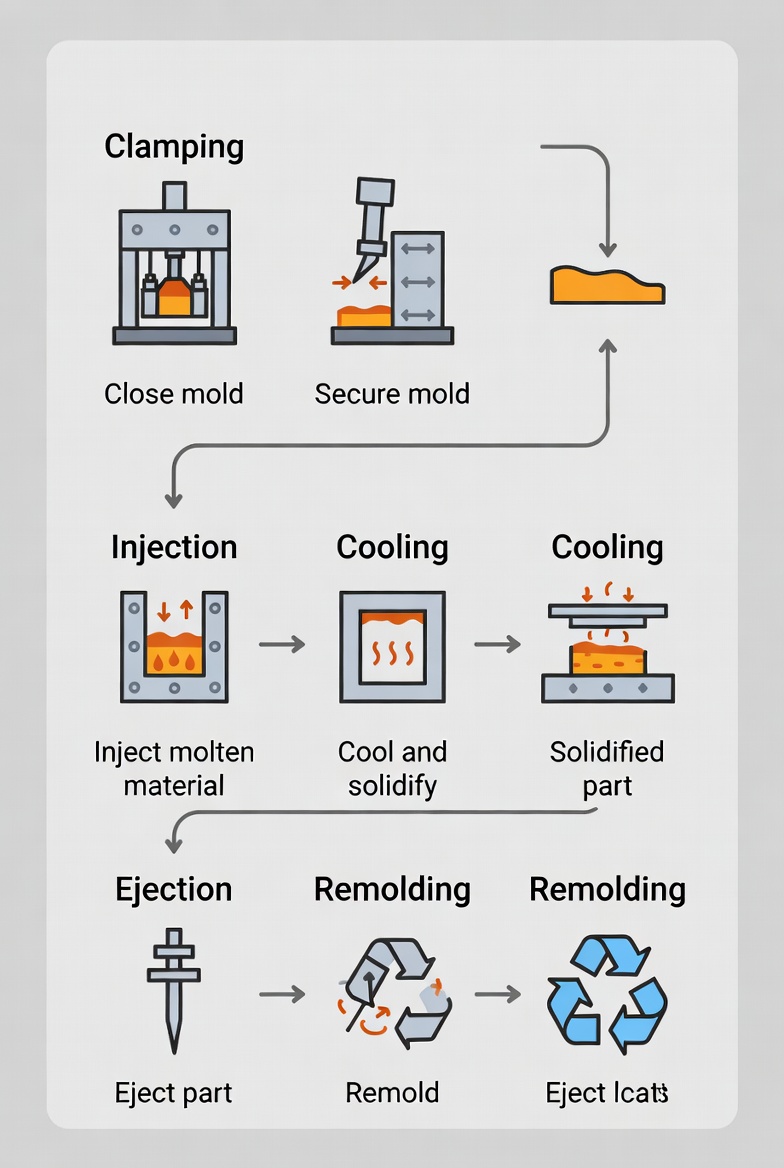

1.Clamping: The mold halves are closed and securely clamped together by the machine's clamping unit to withstand injection pressure.

2.Injection: Plastic pellets (usually thermoplastics like ABS, polypropylene, or polycarbonate) are fed into the hopper. They enter the heated barrel, where the rotating screw melts them through heat and shear friction. The molten plastic is then injected at high pressure (via the screw acting as a plunger) through the nozzle into the mold cavity.

3.Packing/Holding: Additional pressure is applied to pack more material into the cavity, compensating for shrinkage as the plastic begins to cool. Air escapes through vents.

4.Cooling: The molten plastic cools and solidifies inside the mold (often aided by cooling channels circulating water). This is usually the longest phase.

5.Ejection: Once solidified, the mold opens, and ejector pins push the finished part out. The part may drop or be removed robotically.

6.Cycle Repeat: The mold closes again, and the process restarts. Excess material (sprue/runner) is trimmed or recycled.

Illustrations of the overall process and steps:

Important Considerations

1.Materials: Thermoplastics are most common as they can be remelted; thermosets cure permanently.

2.Parameters: Temperature, pressure, injection speed, and cooling time must be optimized to avoid defects like warping, sink marks, or flash.

3.Safety and Setup: This requires specialized equipment and expertise—it's not a DIY process at home due to high pressures (up to 20,000+ psi) and temperatures (200–300°C).