Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to maintain the parts of injection mold?

Understanding Injection Mold Components

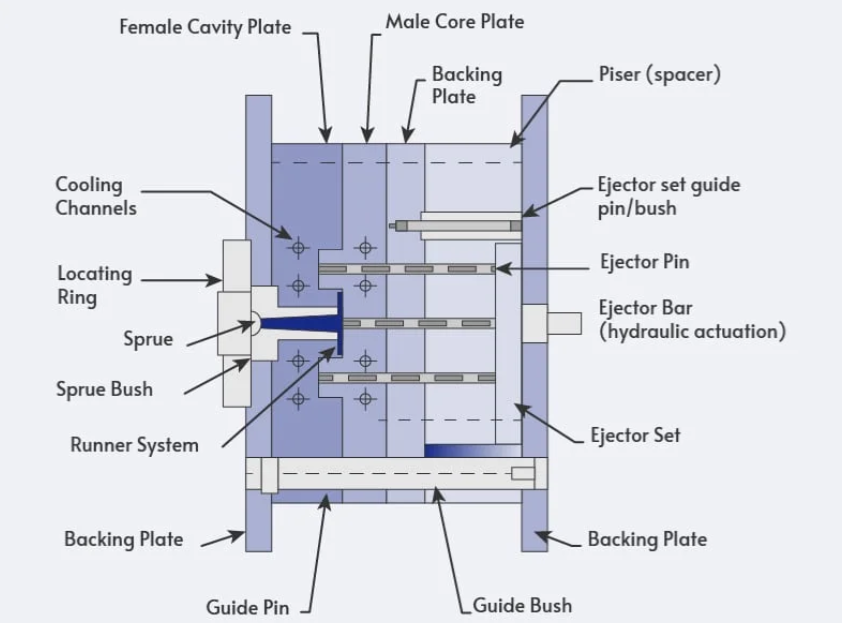

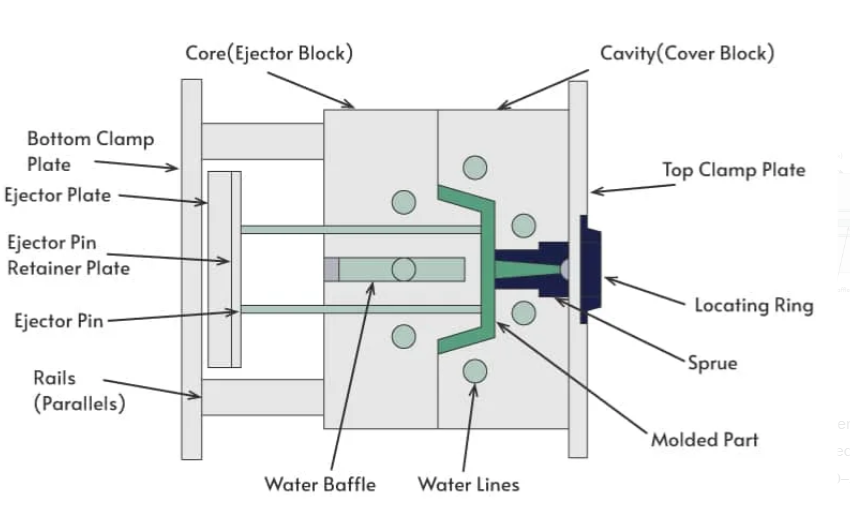

Injection molds consist of several key parts that require specific care to ensure longevity and performance. Common components include:

1.Core and Cavity: Form the shape of the part.

2.Ejector Pins: Push the cooled part out of the mold.

3.Cooling Channels: Regulate temperature for proper solidification.

4.Slides, Lifters, and Guides: Handle undercuts and moving features.

5.Vents: Allow gas escape to prevent defects.

6.Runners and Gates: Direct molten plastic flow.

Here are diagrams illustrating typical injection mold structures:

Best Practices for Maintaining Injection Mold Parts

Proper maintenance extends mold life (often to millions of cycles), reduces downtime, prevents defects like flash or sticking, and ensures consistent part quality. Follow a preventive schedule based on cycles, resin type, and usage—typically daily/after runs, weekly, and major overhauls every 50,000–500,000 shots.

1. Daily/After-Production Cleaning

A.Clean cores, cavities, vents, and ejector areas to remove resin residue, gases, and debris.

B.Use mild solvents, compressed air, or specialized mold cleaners (avoid harsh chemicals that damage coatings).

C.Advanced methods: Dry ice blasting (in-press, non-abrasive), ultrasonic cleaning, or chemical flushing for cooling channels.

D.Focus on vents (prevent burns/short shots) and gates/runners (avoid flow issues).

Here are examples of mold cleaning and maintenance in practice:

2. Inspection

A.Visually check for wear, cracks, corrosion, flash on parting lines, or damage on high-stress areas (gates, ejector pins, slides).

B.Inspect cooling channels for scale/biofilm buildup (flush regularly to maintain heat transfer).

C.Test alignment and moving parts for smooth operation.

3. Lubrication

A.Apply mold-safe lubricant to ejector pins, slides, lifters, and guide pins to prevent seizing and wear.

B.Avoid over-lubrication to prevent contamination.

4. Polishing and Repairs

A.Polish surfaces lightly if needed (maintain finish without altering dimensions).

B.Replace worn parts like ejector pins or O-rings promptly.

C.Address issues like clogged vents or misaligned cores immediately.

5. Storage

A.When not in use, clean thoroughly, apply rust preventive, separate plates if possible, and store in a dry, controlled environment.

B.Cover to protect from dust.

6. Documentation and Scheduling

A.Track cycles with a shot counter.

B.Log all maintenance, issues, and repairs for predictive planning.

C.Train operators on proper handling.