Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is the specific anodizing processes used for pure aluminum, or perhaps the cost implications compared to standard die casting?

1. Anodizing Pure Aluminum vs Alloys

The most striking difference between pure aluminum and standard die-casting alloys is the visual result after anodizing.

A.The Problem with Alloys (ADC12/A380): These alloys contain high amounts of Silicon (up to 12%). During the anodizing process, the acid eats away the aluminum but leaves the silicon particles behind. This results in a "dirty" gray, mottled, or blackish finish. You can’t get bright colors or a clean "metallic" look.

B.The Pure Aluminum Advantage: Because there is virtually no silicon, the anodic oxide layer is transparent and uniform.

Brilliant Colors: You can achieve vibrant reds, blues, or golds that look "deep" and premium.

Texture Retention: It preserves the sandblasted or brushed texture of the metal perfectly.

Hard Anodizing: You can create a very thick, wear-resistant layer that is much more durable than the layer formed on standard alloys.

2. Cost Implications

Pure aluminum die casting is significantly more expensive than standard die casting. Here is why the price is higher:

A. Raw Material Costs

While aluminum ingot prices fluctuate, the high-purity ingots (99.7%+) carry a premium over recycled or standard alloys.

B. Shorter Tooling Life (The Biggest Cost Factor)

Thermal Shock: Because pure aluminum has a higher melting point, the steel molds (dies) experience higher thermal stress.

Erosion: Molten pure aluminum is "chemically hungry" for iron. It attacks the steel mold surfaces more aggressively (soldering).

Result: A mold that might last 100,000 shots with ADC12 might only last 30,000 to 50,000 shots with pure aluminum before needing expensive repairs or replacement.

C. Higher Scrap Rates

The "sluggish" flow of pure aluminum means you will likely have more "short shots" (parts that didn't fill completely) or surface ripples during the start-up phase. You pay for this lower yield in the per-piece price.

D. Specialized Equipment

To do this well, manufacturers often use Vacuum Die Casting machines. These extract air from the mold to help the "sluggish" metal fill the cavity. This equipment is more expensive to operate than standard machines.

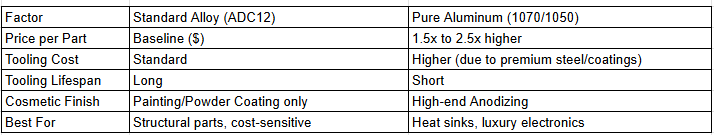

3. Summary Comparison Table