Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Which tool steel is right for your plastic injection mold?

Choosing the right tool steel is a balance between initial cost, production volume, and the chemical nature of the plastic you are molding. Using the wrong steel can lead to premature wear, cracking, or corrosion from outgassing.

The following guide breaks down the most common choices by their primary "job description."

1. The General Purpose Workhorse: P20

If you aren’t sure where to start, you’re likely looking at P20. It is a low-alloy, pre-hardened steel.

Best For: Moderate production runs (up to 100,000 shots) and large mold bases.

Pros: It doesn't require heat treatment after machining (saving time/cost) and is very easy to machine.

Cons: Not suitable for abrasive plastics (like glass-filled nylon) or extremely high volumes.

2. The High-Volume "Tough Guy": H13

When you need a tool to last for 500,000 to 1 million cycles, H13 is the standard.

Best For: High-volume production and engineering plastics.

Pros: Excellent toughness and resistance to thermal fatigue (heat checking). It is usually through-hardened.

Cons: It is prone to rusting if not maintained, and the heat-treatment process adds cost and time.

3. The Corrosion Specialist: 420 Stainless (S136)

Certain plastics, like PVC, release corrosive gases during the molding process. Standard tool steels will "pit" and rust almost immediately.

Best For: Corrosive resins (PVC, some flame retardants), medical parts, and high-gloss/mirror finishes.

Pros: Exceptional rust resistance and takes a high polish.

Cons: Lower thermal conductivity (parts take longer to cool) and higher material cost.

4. The Impact Expert: S7

If your mold has thin walls or delicate "fingers" that might snap under the high pressure of injection, S7 is the choice.

Best For: Molds with complex geometry or high-impact requirements.

Pros: Incredible shock resistance and dimensional stability during heat treat.

Cons: Not as wear-resistant as H13.

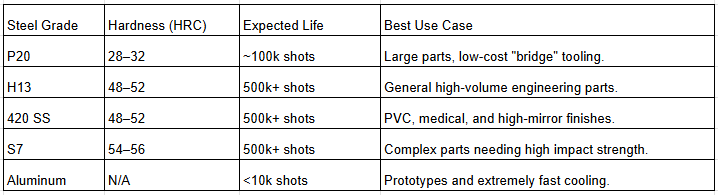

Comparison at a Glance