Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Can abs and nylon use the same injection mold?

Yes, ABS and Nylon (typically PA6 or PA66) can technically use the same injection mold, as both are thermoplastics commonly processed via injection molding, and molds are often made from tool steels that can handle either material.

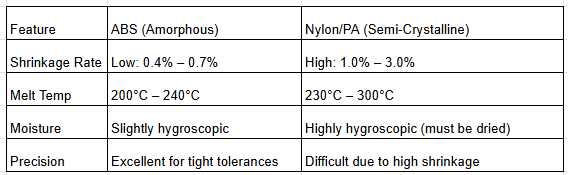

However, it is not always recommended without adjustments, primarily due to differences in material properties.While you can physically inject both materials into the same mold, they behave differently as they cool. Because Nylon shrinks much more than ABS, a part made of Nylon will come out smaller than the same part made of ABS, even if they were both formed in the exact same mold cavity.

Key Technical Differences

To understand why they aren't perfectly interchangeable, consider these three factors:

1. The "Shrinkage" Problem

This is the biggest hurdle. When an engineer designs a mold, they "oversize" the cavity to account for the plastic's shrinkage.

If the mold was designed for ABS: A Nylon part will shrink too much, leading to loose fits, dimensional errors, or internal "sink marks."

If the mold was designed for Nylon: An ABS part will be "too big" and may get stuck in the mold or fail to fit into its intended assembly.

2. Gating and Venting

Nylon has a lower viscosity (it's "runnier") when melted than ABS.

Flash: If you put Nylon into a mold designed for ABS, the "runny" Nylon might leak into the tiny gaps between mold plates, creating thin flaps of extra plastic called flash.

Venting: ABS requires deeper vents to let air out. If these vents are used for Nylon, the Nylon might plug them up or create more flash.

3. Processing Differences

Temperature: Nylon requires much higher barrel and mold temperatures. If your mold’s cooling/heating system isn't rated for the higher heat required for Nylon, you could damage the seals or the mold itself.

Ejection: Because Nylon is more flexible than ABS when warm, it may require more or larger ejector pins to push it out of the mold without deforming the part.

When can you use the same mold?

You can use the same mold if:

Dimensions don't matter: If the part is a simple stand-alone item (like a toy or a handle) where a 1–2% difference in size doesn't affect its function.

Using Filled Materials: If you use Glass-Filled Nylon, its shrinkage rate drops significantly (often down to 0.3% – 1.0%), which brings it much closer to the shrinkage rate of standard ABS.

In practice:

For prototyping or low-volume runs, the same mold can often be used with process tweaks.

For high-precision or high-volume production, separate molds (or at least mold modifications for shrinkage compensation) are preferable to ensure consistent quality.

Some manufacturers successfully switch materials in the same mold by adjusting parameters and using purge compounds, but dimensional tolerances must be verified.