Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What are non manifold edges in 3d printing?

In 3D printing, non-manifold edges are edges in a 3D model's mesh (typically triangles) that break the rules of "manifold" (or "watertight") geometry. A manifold model behaves like a real-world solid object: it has a clearly defined inside and outside, no holes (unless intentional), and forms a closed, continuous surface—like an inflated balloon with thickness.

What Makes an Edge Non-Manifold?

In a proper manifold mesh, every edge connects exactly two faces (triangles). Non-manifold edges violate this in ways such as:

a.Shared by more than two faces — e.g., three or more triangles meet at one edge (like a "T" or "+" junction where a wall protrudes inward without proper closure).

b.Boundary or naked edges — edges with only one face (or zero), often indicating holes or open surfaces.

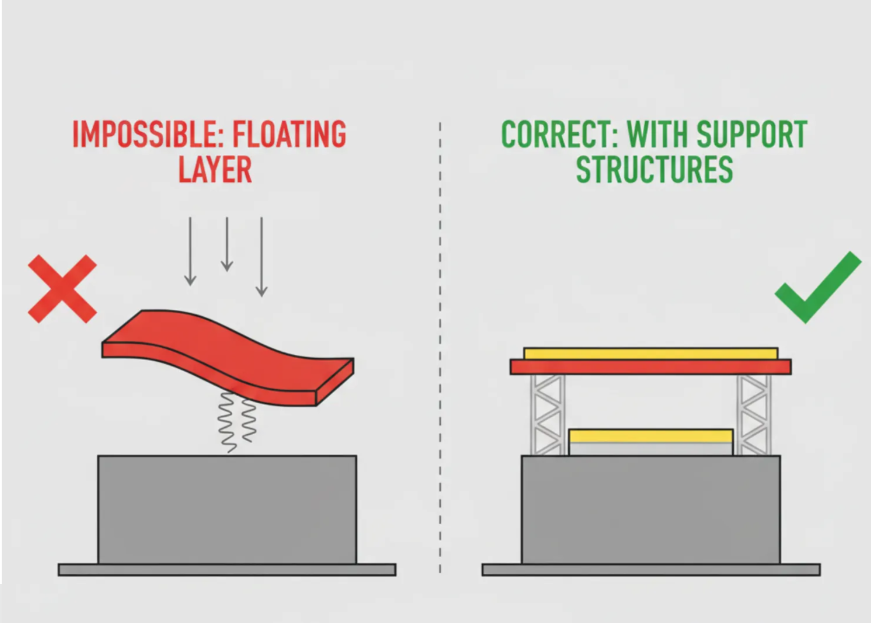

c.Internal or floating geometry — extra faces/edges inside the model or disconnected parts.

d.Overlapping or duplicate geometry — edges/vertices occupying the same space without merging.

Why Are They a Problem for 3D Printing?

Slicing software (e.g., Cura, PrusaSlicer) needs to determine exactly where material should go by calculating the volume enclosed by the mesh. Non-manifold edges confuse this process because the geometry can't exist physically—it creates ambiguous "inside/outside" regions, zero-thickness walls, or undefined volumes. This can lead to:

a.Slicing errors or failures.

b.Missing parts, extra artifacts, or failed prints.

c.Unexpected infill/walls in the final model.

Many slicers detect and warn about (or auto-fix minor) non-manifold issues, but severe ones require manual repair.

How to Fix Them

Common fixes include merging vertices, closing holes, deleting internal faces, or remodelling problematic areas.For printable models, always aim for manifold geometry to avoid headaches!