Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is the fastest way to Physical Products prototype?

The fastest way to prototype a physical product depends on the stage (concept vs. functional) and complexity, but here are the top methods ranked by speed:

1.Handmade/Low-Fidelity Prototypes (Hours to 1-2 Days)

The absolute quickest for early validation of form, size, or ergonomics. Use cardboard, foam, clay, wire, or everyday materials to build a rough "looks-like" model.

Pros: Extremely fast, cheap, no tools needed.

Cons: Low detail, not functional.

Ideal for initial ideas or user testing.

2.Modifying Existing Products (1-3 Days)

Buy off-the-shelf items (e.g., via Amazon or Alibaba) similar to your idea and hack/modify them with glue, tape, or basic tools.

Pros: Very quick, realistic feel.

Cons: Limited to what's available.

Great for proof-of-concept without starting from scratch.

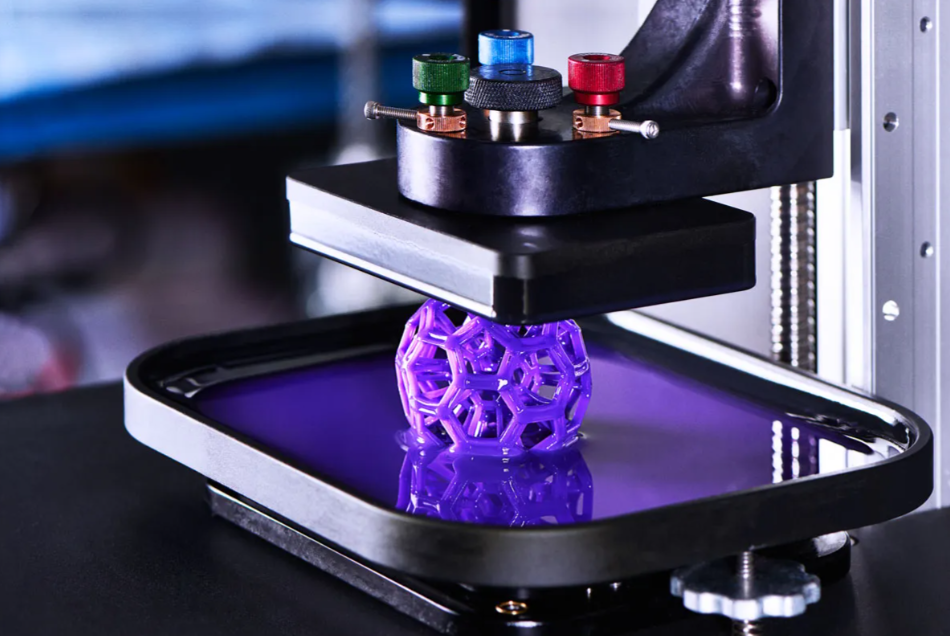

3.3D Printing (1-7 Days, Often Same-Day In-House)

The go-to for modern rapid prototyping. Design in CAD (free tools like Tinkercad or Fusion 360), then print. Desktop printers (e.g., FDM like Prusa or resin like Formlabs) can produce parts in hours. Services offer 1-3 day turnaround.

Pros: Handles complex geometries, iterative quickly.

Cons: Material strength varies; post-processing needed for finish.

In 2025-2026, advancements in speed (e.g., high-speed resin printers) make this even faster.

4.CNC Machining (3-10 Days)

Subtracts material from blocks for high-precision parts in metals/plastics. Quick for functional prototypes.

Pros: Excellent accuracy and material properties.

Cons: Slower than 3D printing for complex shapes.