Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Compare 3D printing vs CNC

Choosing between 3D printing and CNC machining often depends on whether you value geometric complexity or structural precision.

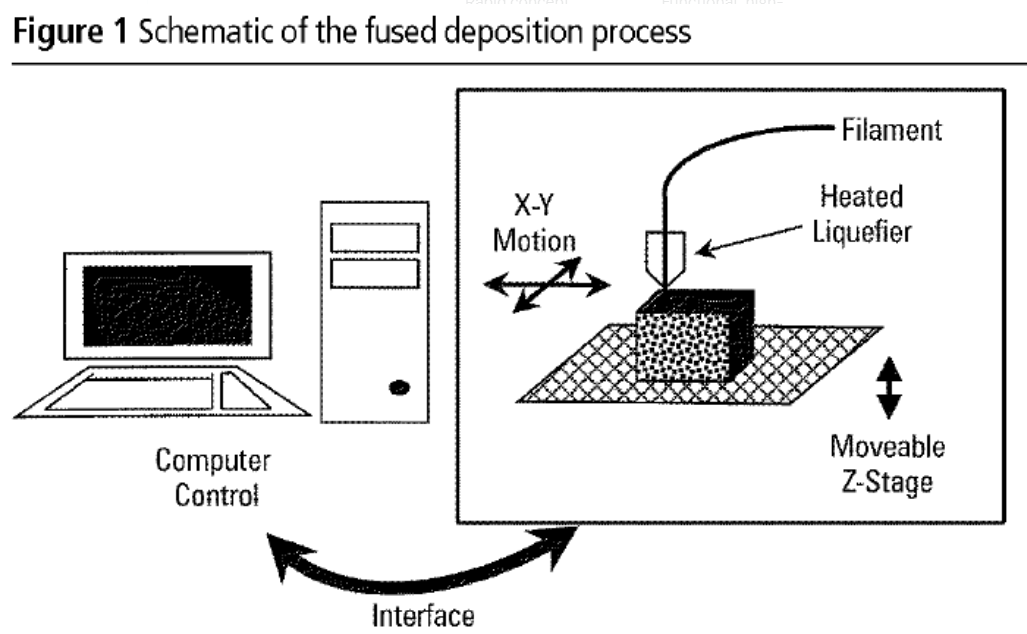

At a fundamental level, 3D printing is additive (adding material layer-by-layer), while CNC is subtractive (cutting material away from a solid block)

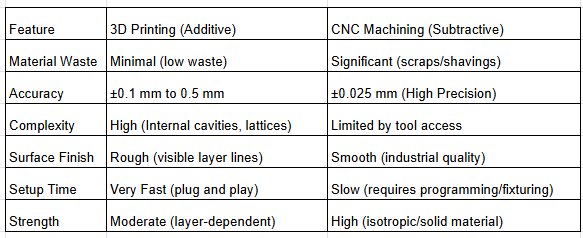

Quick Comparison Table

When to Choose 3D Printing

3D printing is the go-to for "innovation speed" and parts that are physically impossible to carve out.

1.Rapid Iteration: You can go from a digital design to a physical part overnight. It is much cheaper for producing 1–10 units.

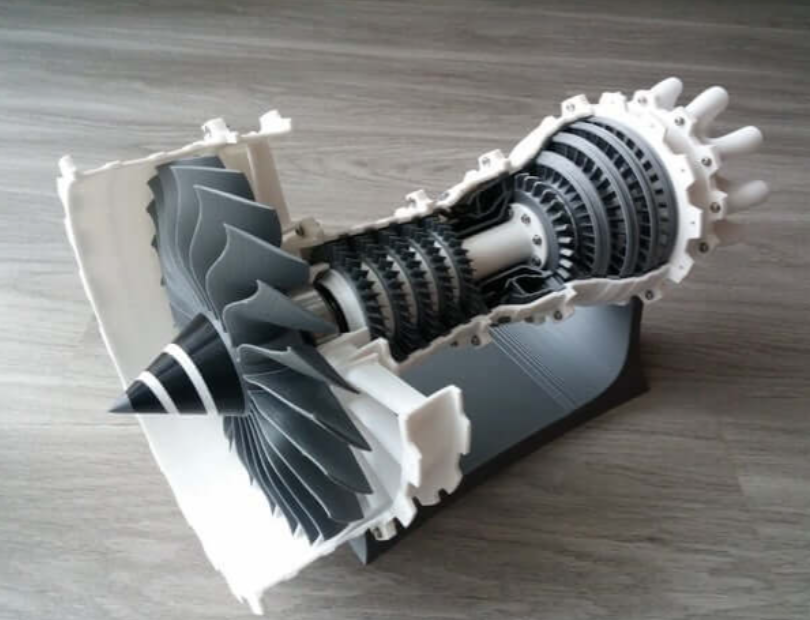

2.Complex Geometries: If your design includes internal channels (like for cooling) or organic, lattice-like structures, 3D printing is often the only option.

3.Lightweighting: Ideal for aerospace or medical applications where you need to reduce weight without sacrificing all structural integrity.

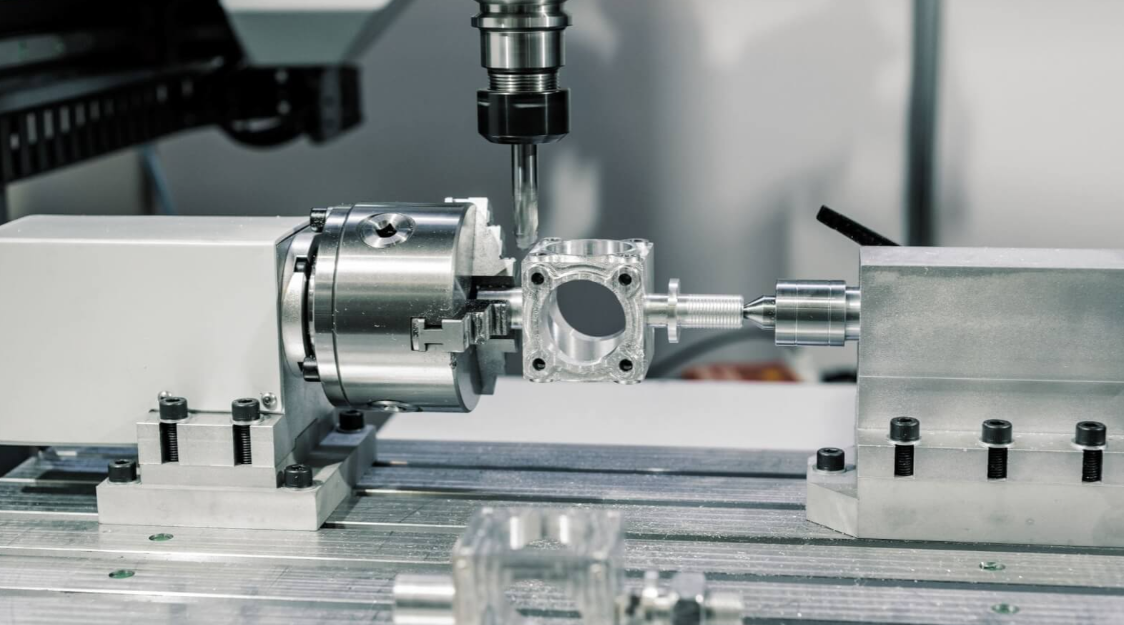

When to Choose CNC Machining

CNC is the gold standard for "functional reliability" and mass production.

1.High Precision: If you need parts to fit together perfectly (like engine components or gears), the ± 0.025 mm tolerances of CNC are necessary.

2.Material Properties: CNC uses solid blocks of "real" materials (aluminum, stainless steel, wood).

3.This results in parts that are much stronger and have consistent properties in all directions.Scalability: While the setup is expensive and slow, the "run time" for each part is often faster than a 3D printer.For batches of 50–200+ parts, CNC becomes more cost-effective.