Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is cnc foam prototyping?

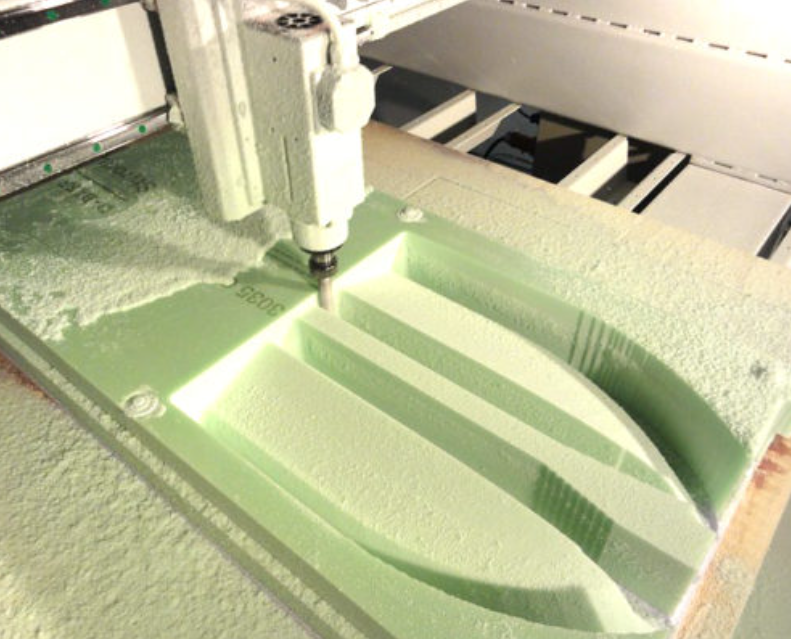

CNC foam prototyping is a rapid prototyping technique that uses Computer Numerical Control (CNC) machines to precisely cut, mill, or shape foam materials into 3D models or prototypes. Designers create a digital 3D model (typically in CAD software), which the CNC machine follows via programmed toolpaths to remove material from a foam block, producing accurate physical representations quickly and cost-effectively.

Common Methods

CNC milling/routing — Rotating bits carve the foam for complex geometries and fine details.

Hot wire cutting — A heated wire melts through the foam, ideal for smooth curves and large-scale shapes (often used for EPS or XPS foams).

Common Foam Materials

EPS (Expanded Polystyrene) → Lightweight and inexpensive, great for large mockups.

Polyurethane (PU) or high-density urethane (HDU) → For smoother finishes and higher detail.

EVA, EPE, or tooling boards → For specific applications like molds or durable prototypes.

Advantages

Low cost — Foam is cheap, and no custom molds are needed (unlike injection molding).

Speed — Ideal for quick iterations in product development.

Large-scale capability — Easily handles big prototypes (e.g., automotive or aerospace models) that are difficult with other methods.

Precision — Achieves tight tolerances for form, fit, and visual testing.

Applications

Product design validation (e.g., concept models for consumer goods).

Automotive/aerospace mockups.

Architectural models.

Props for film/theater.

Custom packaging inserts.

Molds for composites or casting.

Here are some examples of CNC-cut foam prototypes and machining in action: