Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is squeezing die casting?

Squeeze die casting, also known as squeeze casting or liquid metal forging, is a hybrid manufacturing process that combines elements of die casting and forging. It produces high-integrity metal parts with superior mechanical properties, minimal porosity, and dense microstructures by solidifying molten metal under high pressure in a closed die.

How Squeeze Die Casting Works

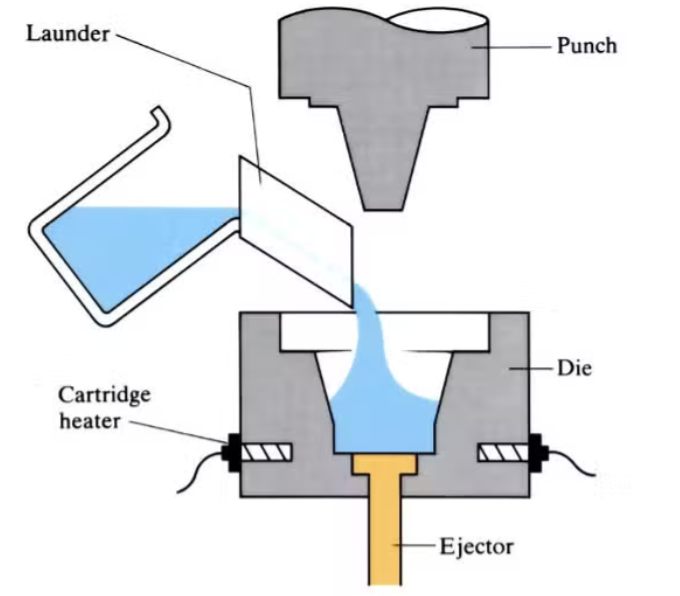

1.The process typically involves these steps:A precise amount of molten metal (commonly aluminum, magnesium, zinc, or copper alloys) is poured into a preheated and lubricated die cavity.

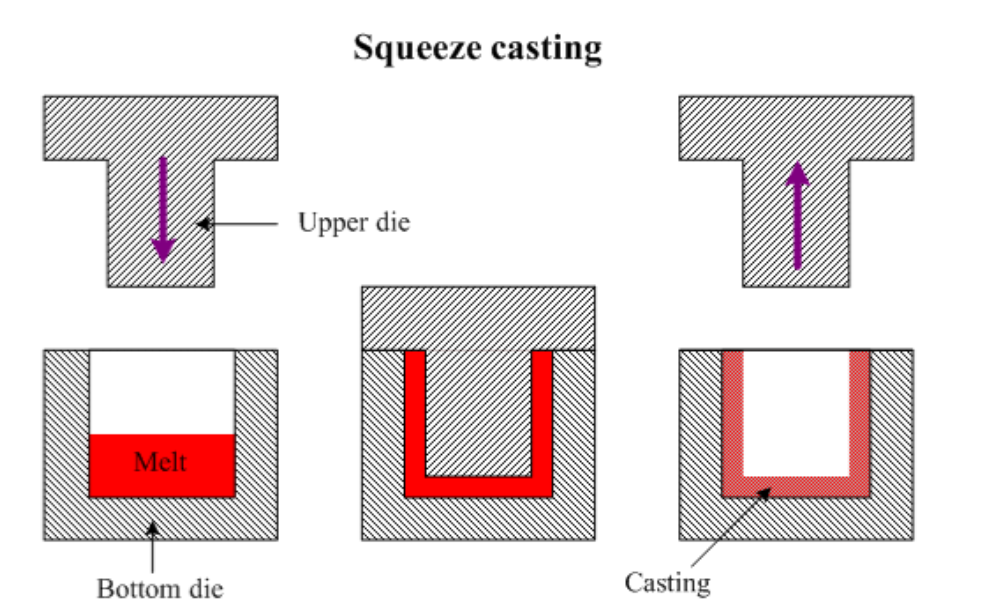

2.The die closes, and high pressure (often 70–300 MPa) is applied via a hydraulic press or ram as the metal begins to solidify.

3.The sustained pressure forces the metal to fill the cavity completely, eliminates shrinkage and gas porosity, and refines the grain structure through rapid heat transfer.

4.Once fully solidified, the part is ejected.

There are two main variants:

Direct squeeze casting — Molten metal is poured directly into the open lower die, then the upper punch closes and applies pressure.

Indirect squeeze casting — Similar to high-pressure die casting, metal is injected through a sleeve and thicker gate at low velocity (<0.5 m/s) before pressurization.

Key Advantages Over Conventional High-Pressure Die Casting

Reduced porosity → Virtually eliminates gas and shrinkage defects, allowing parts to be heat-treated, welded, and pressure-tight.

Superior mechanical properties → Higher strength, ductility, and fatigue resistance due to finer grains (often approaching forged part performance).

Better integrity → Suitable for critical structural components.

However, it has slower cycle times and higher costs per part compared to standard die casting, making it ideal for lower-volume, high-performance applications.

Common Applications

Automotive parts (e.g., wheels, suspension components, engine blocks), aerospace components, and high-strength industrial parts requiring durability and lightweight properties.