Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How a die cast mold is made?

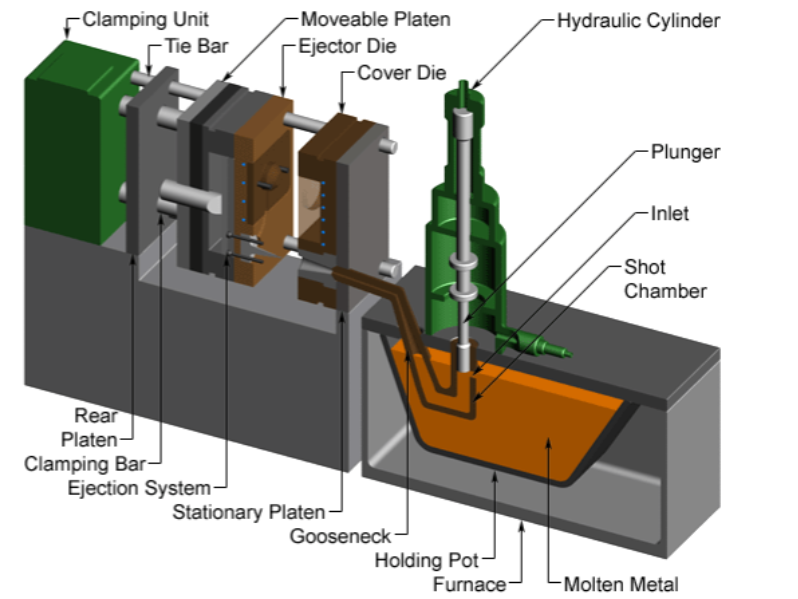

A die cast mold (also called a die) is a precision tool used in high-pressure die casting to produce metal parts by injecting molten metal (typically non-ferrous alloys like aluminum, zinc, or magnesium) into a cavity under high pressure. These molds are made from hardened tool steel to withstand extreme temperatures, pressures, and thousands to millions of cycles.

The process of making a die cast mold is highly precise and involves engineering, simulation, and advanced machining. Here are the main steps:

1.Part Design and Manufacturability Analysis

Engineers start with the desired part's specifications. They use CAD software to create a 3D model and perform Design for Manufacturability (DFM) analysis. This includes checking wall thickness, draft angles (tapers for easy ejection), fillets, and feasibility with die casting. Flow simulation software (e.g., MAGMA or CAE tools) predicts metal flow, cooling, and potential defects like porosity or shrinkage.

2.Mold Design

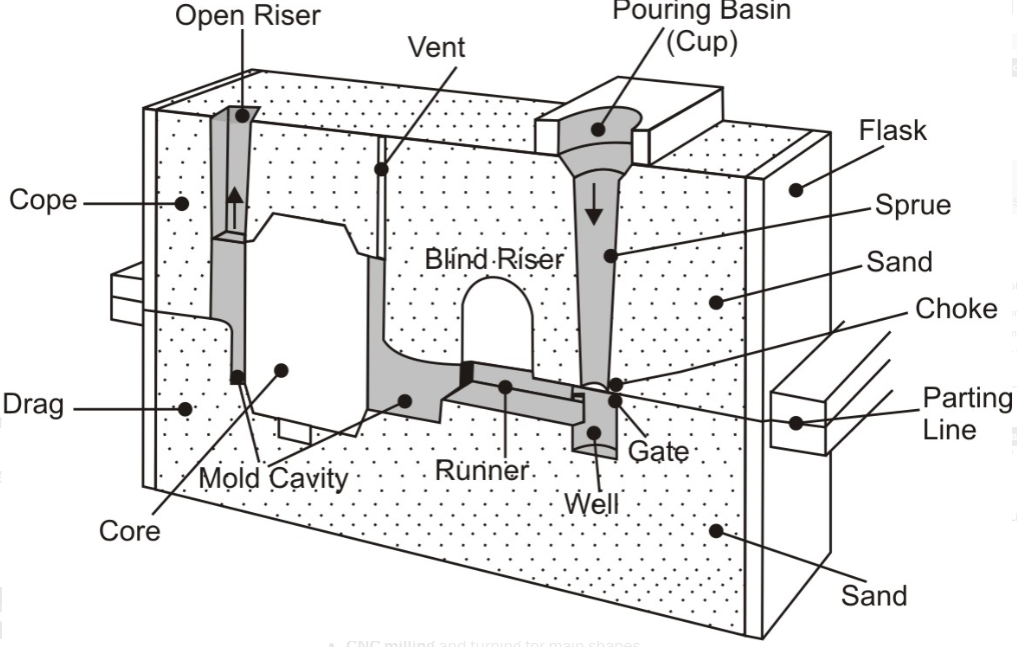

Designers create the mold layout, including the cavity (shaped like the part), cores (for internal features), runners/gates (channels for metal flow), cooling channels, ejector pins, and parting line (where the two halves meet). Factors like number of cavities (single or multi), overflow vents, and slide mechanisms for undercuts are decided. Simulations optimize for uniform filling and cooling.

3.Material Selection

Premium hot-work tool steels like H13 or H11 are commonly used for the cavity and core inserts due to their heat resistance, toughness, and wear resistance. The mold base may use milder steels.

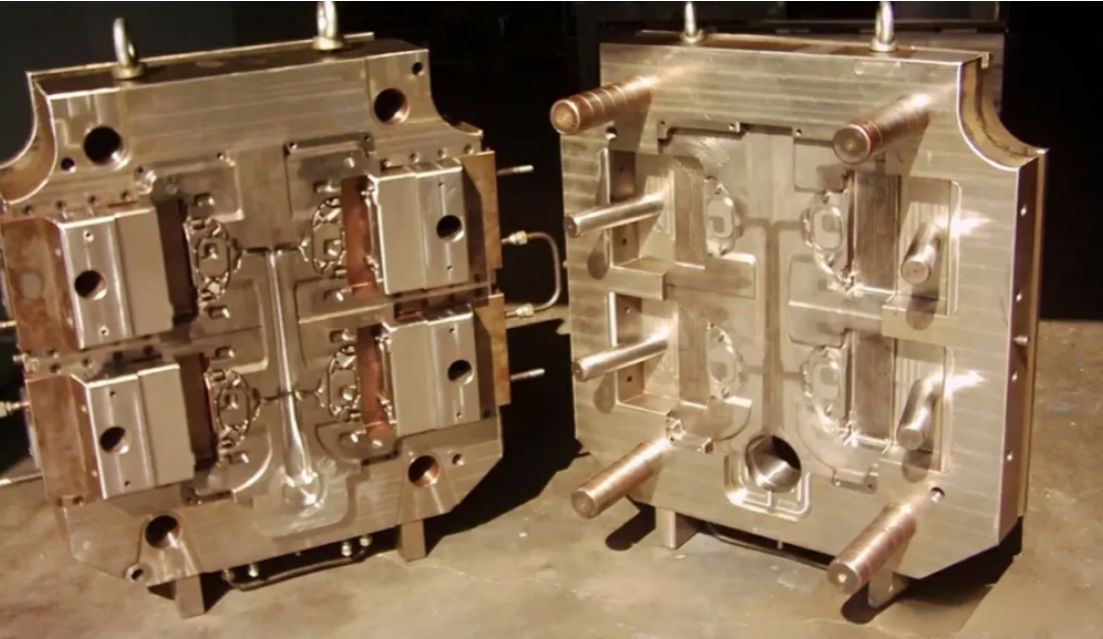

4.Machining and Fabrication

Steel blocks are rough-machined. Precision techniques include:

a.CNC milling and turning for main shapes.

b.Electrical Discharge Machining (EDM) for fine details and sharp corners.

c.Drilling for cooling lines and ejector pins.

Inserts are often machined separately and fitted into the mold base.

5.Heat Treatment and Surface Finishing

Components are heat-treated (quenched and tempered) to achieve hardness (typically 46-48 HRC). Surfaces are polished for smooth part release, and coatings (e.g., nitriding) may be applied for longevity.

6.Assembly and Testing

The two halves (fixed/cover die and movable/ejector die) are assembled with guides, clamps, and cooling systems. Trial runs inject metal to produce sample parts. Adjustments are made for defects, and the mold is validated for production.

This process can take weeks to months and costs tens of thousands of dollars, but a well-made mold enables high-volume, consistent production with excellent surface finish and dimensional accuracy. Maintenance (cleaning, lubrication) extends mold life significantly.