Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How is die casting different than permanent mold casting?

Overview of Die Casting and Permanent Mold Casting

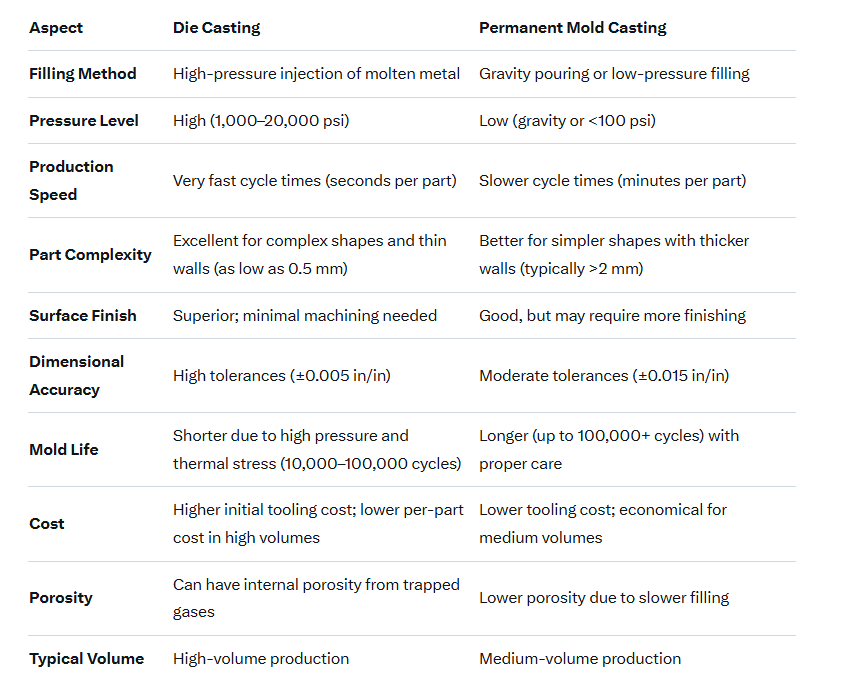

Both die casting and permanent mold casting are metal casting processes that use reusable molds (typically made of metal like steel or iron) to produce parts. They are commonly used for non-ferrous metals such as aluminum, zinc, magnesium, and copper alloys. However, they differ in several key aspects, including the method of filling the mold, production speed, part complexity, and applications.

Die Casting

1.In die casting, molten metal is injected into the mold cavity under high pressure (typically 1,000 to 20,000 psi) using a machine.

2.The process allows for rapid production of complex, thin-walled parts with excellent dimensional accuracy and surface finish.

3.There are two main types: hot-chamber (for low-melting metals like zinc) and cold-chamber (for higher-melting metals like aluminum).

4.It's ideal for high-volume manufacturing, such as automotive parts, electronics housings, and consumer goods.

Permanent Mold Casting

1.In permanent mold casting (also known as gravity die casting), molten metal is poured into the mold under gravity or low pressure (often less than 100 psi), without high-force injection.

2.The mold is preheated and may be coated with a refractory material to extend its life and improve release.

3.It's suitable for medium-volume production of simpler shapes with thicker walls, offering good mechanical properties but potentially requiring more post-processing.

4.Common applications include pistons, wheels, and pump housings.

Key Differences