Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to make die cast mold?

Making a die-cast mold (often called a "die") is a high-precision engineering process because the mold must withstand extreme heat and immense pressure (up to 140 MPa) over thousands of cycles.

The process is generally divided into three phases: Design, Machining, and Finishing.

1. Design & Engineering

Before cutting any metal, the mold is built virtually using CAD (Computer-Aided Design) software.

a.Parting Line: You must determine where the two halves of the mold (the "cover" and "ejector" sides) will meet.

b.Draft Angles: All vertical walls must have a slight taper (usually 1° to 2°) so the part can slide out without sticking.

c.Shrinkage Allowance: Since metal shrinks as it cools, the mold cavity must be designed slightly larger than the final part.

d.The Runner System: You design the "plumbing" of the mold—the sprue (entry point), runners (tunnels), and gates (entries to the cavity) that control how molten metal fills the space.

2. Material Selection

Die-cast molds are almost always made from high-grade Hot-Work Tool Steels.

a.H13 Tool Steel: The industry standard. It has excellent "red hardness," meaning it stays strong even when glowing hot.

b.Maraging Steel: Used for very high-volume production or complex parts due to its extreme strength.

3. The Manufacturing Process

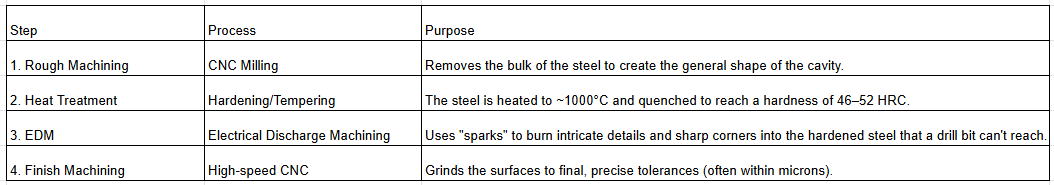

Once the design is ready, the physical mold is created using several machining steps:

4. Assembly & Finishing

The mold is more than just a block of steel; it is a complex machine.

a.Ejection System: You must install ejector pins that push the solidified part out of the mold.

b.Cooling Lines: Drilled holes throughout the mold where water or oil circulates to regulate the temperature.

c.Polishing: The cavity is polished to the desired surface finish. A mirror-like polish on the mold results in a smooth finish on the metal part.

d.Venting: Tiny "exhaust" channels (0.05mm–0.1mm deep) are added to allow air to escape as the metal rushes in.

Important Considerations

a.Wall Thickness: Aim for uniform wall thickness in your part design. Sudden changes in thickness cause "sink marks" or air pockets (porosity).

b.Fillets: Never use sharp 90-degree internal corners; always use a radius (fillet) to help the metal flow and prevent the mold from cracking.