Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How might we design tool(mold )?

Designing effective tools—whether they are physical hammers or complex digital interfaces—is a blend of psychology, engineering, and empathy. At its core, great design is about reducing the distance between a user’s intent and the final result.

Here is a framework for how we should approach tool design:

1. Analyze the Part Design (DFM)

Before designing the mold, you must optimize the part itself. This is called Design for Manufacturability (DFM).

Uniform Wall Thickness: Aim for consistent thickness to prevent "sink marks" (dents) or warping as the material cools.

Draft Angles: Add a slight taper (usually 1° to 3°) to vertical walls so the part can slide out of the mold without friction.

Radiused Corners: Replace sharp 90° corners with curves. This improves material flow and prevents structural weak points in the mold.

2. Determine the Parting Line

The Parting Line is where the two halves of the mold (the "A-side" and "B-side") meet.

Placement: Place it on an edge where the resulting "flash" (a thin line of excess material) won't be visible or interfere with the part's function.

Split: The mold usually splits into a Cavity (the "show" side or exterior) and a Core (the interior or "moving" side)

3. Design the Feed System

This is the plumbing that gets the molten material into the cavity.

Sprue: The main entry point for the material.

Runners: Channels that distribute the material to various parts of the mold.

Gates: The narrow opening where material enters the actual part cavity. The gate's location affects the strength and appearance of the final part.

4. Manage Physics: Cooling and Ejection

A mold is a heat exchanger. If it doesn't cool evenly, the part will deform.

Cooling Channels: These are holes drilled through the mold base where water or oil circulates to pull heat away.

Ejection System: Once the part is solid, Ejector Pins push it out of the mold. You must place these on the "non-show" side of the part because they often leave small circular marks.

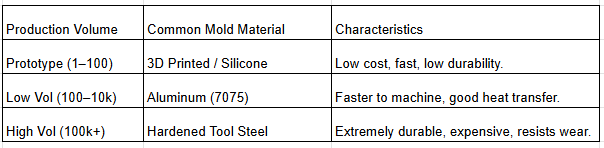

5. Material Selection for the Mold

The "tool" material depends on your production volume:

6.Mold Design Checklist

Shrinkage: Did you scale the cavity up to account for the material shrinking as it cools? (e.g., ABS shrinks roughly 0.5%).

Venting: Are there tiny paths for air to escape? If not, trapped air will compress, heat up, and burn the material.

Undercuts: Does the part have holes or tabs that would get "stuck" when the mold opens? If so, you’ll need Slides or Lifters (moving parts inside the mold).