Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to choose the best prototype production solution based on the actual situation?

Choosing the best prototyping solution is a balance between your current project stage, functional requirements, and budget. There is no "one-size-fits-all" method; rather, the best choice depends on what question the prototype needs to answer.

Here is a guide to selecting the right method based on your specific situation.

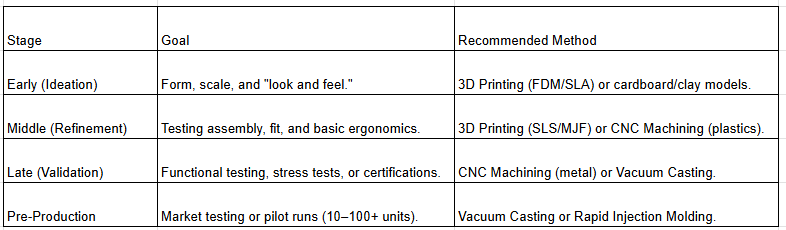

1. Identify Your Project Stage

The "fidelity" (realism) of your prototype should match how close you are to the final product.

2. Choose by Primary Requirement

If your project has a "deal-breaker" requirement, use this list to narrow down your options:

a.Need High Strength/Durability?

CNC Machining is king. It uses real engineering-grade metals and plastics (like Aluminum 6061 or Stainless Steel) that perform exactly like the final part.

b.Need Intricate Geometries?

3D Printing (SLA or SLS) can create internal lattices and hollow structures that are impossible to machine with a drill bit.

c.Need a "Consumer-Ready" Surface?

Vacuum Casting produces parts that look and feel like injection-molded plastic straight out of the mold, including textures and colors.

d.Need Extreme Precision?

CNC Machining offers tolerances as tight as ±0.025 mm, whereas most 3D printersrange from ±0.lmm to ±0.3 mm.

3. Consider Quantity and Cost

The "sweet spot" for cost-effectiveness changes as your quantity increases.

a.1–5 Units: 3D Printing is almost always the cheapest because there is zero setup or "tooling" cost.

b.10–50 Units: Vacuum Casting becomes viable. You pay for one "master" model and a silicone mold, then the cost per part drops significantly.

c.100+ Units: CNC Machining (for metal) or Rapid Tooling/Injection Molding (for plastic) becomes more economical as the setup costs are "amortized" across many parts.

4. Decision Flowchart (Quick Reference)

Ask yourself these three questions in order:

a.Is it a complex internal shape? → Yes? 3D Printing.

b.Does it need to handle high heat or stress? → Yes? CNC Machining.

c.Do I need 20+ copies that look like the real thing? → Yes? Vacuum Casting.

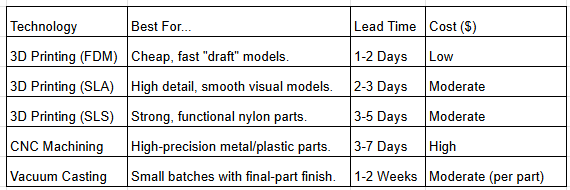

Comparison Table: Prototyping Methods