Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to Make Aluminum Die Casting Prototypes?

Creating an aluminum die-cast prototype is a challenge because true die casting requires expensive, permanent steel tools that are usually not cost-effective for just a few parts. To solve this, engineers use four primary methods depending on whether they need "production-identical" properties or just a visual model.

1. The "True" Prototype: Single-Cavity Unit Dies

If you need 100% accurate testing (functional, thermal, and structural), you must use actual pressure.

a.The Process: Instead of building a massive multi-cavity production tool, a "unit die" is used. This is a smaller, simplified steel insert (often made of softer P20 or H13 steel) that fits into a standard master mold base.

b.Best for: 50–500 parts. It uses the exact alloy and pressure as the final run.

c.Lead Time: 2–4 weeks.

2. The Speed King: CNC Machining ("Hog-outs")

Many "die cast" prototypes aren't cast at all; they are carved from a solid block of aluminum.

a.The Process: A CNC machine removes material from a billet of aluminum (typically 6061 or a casting-simulated alloy).

b.Best for: 1–10 parts. It is the fastest way to get a metal part in hand.

c.Limitation: It cannot perfectly replicate the "skin" or internal porosity of a cast part, which may affect fatigue testing.

3. The Batch Solution: Plaster Mold Casting (RPM)

This is often called the "Rubber Plaster Mold" (RPM) process and is the most common way to simulate a die casting without the steel tool cost.

The Process:

a.A "master" is made (usually via 3D printing/SLA).

b.A silicone rubber mold is created from the master.

c.A liquid plaster slurry is poured into the rubber mold to create a plaster mold.

d.Molten aluminum is poured into the plaster mold (often under a vacuum to help it flow into thin walls).

Best for: 10–100 parts. It mimics the thin walls of die casting very well.

4. The Digital Alternative: 3D Printing (DMLS)

Direct Metal Laser Sintering (DMLS) uses a laser to melt aluminum powder layer by layer.

a.The Process: The machine builds the part directly from a 3D file.

b.Best for: Highly complex geometries that are impossible to machine or cast.

c.Lead Time: 2–5 days.

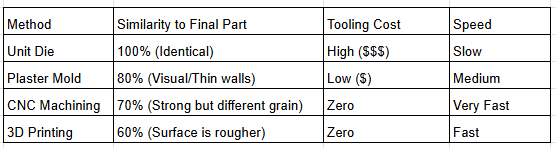

Summary: Which one should you choose?