Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What methods can be used for rapid prototyping?

Rapid prototyping (RP) encompasses a variety of techniques used to quickly fabricate a physical part or assembly using 3D computer-aided design (CAD) data. These methods are generally categorized into three main types: Additive, Subtractive, and Compressive.

1. Additive Manufacturing (3D Printing)

This is the most common form of rapid prototyping. It builds parts layer-by-layer, allowing for extreme geometric complexity that would be impossible with traditional tools.

Fused Deposition Modeling (FDM): The most accessible method. It melts a plastic filament and extrudes it through a nozzle. Ideal for basic form and fit testing.

Stereolithography (SLA): Uses a UV laser to cure liquid resin into solid plastic. It produces very high resolution and smooth surface finishes, perfect for "looks-like" prototypes.

Selective Laser Sintering (SLS): Uses a high-powered laser to fuse small particles of polymer powder (usually Nylon). It is excellent for functional, durable parts because it requires no support structures.

Direct Metal Laser Sintering (DMLS) / SLM: Similar to SLS but uses metal powder. This is used for high-performance prototypes in aerospace or medical industries.

PolyJet: Jets layers of liquid photopolymer onto a build tray and cures them instantly with UV light. It can print multiple materials and colors simultaneously.

2. Subtractive Manufacturing

Unlike additive methods, subtractive manufacturing starts with a solid block of material and removes what isn't needed.

CNC Machining: Computer Numerically Controlled (CNC) tools like mills and lathes carve the part from a "blank" of metal or plastic.

Pros: Superior strength, tight tolerances (土0.005mm), and production-grade materials.

Cons: Higher cost per unit and more material waste.

3. Compressive & Casting Methods

These methods are often used for "bridge production"—the gap between a single prototype and full mass production.

Vacuum Casting: Uses a 3D-printed "master" to create a silicone mold. Resin is then poured into the mold under a vacuum. This is great for small batches (10–50 units) that need to look and feel like injection-molded parts.

Rapid Injection Molding: Uses simplified aluminum molds instead of complex steel ones. It allows you to test the actual material and manufacturing process you'll use in mass production but at a fraction of the traditional lead time.

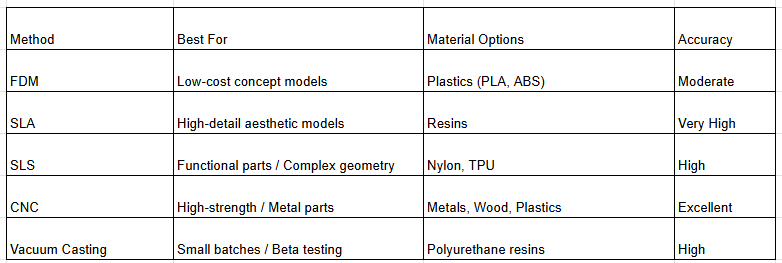

Comparison Table: Choosing the Right Method: