Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is injection molding expensive?

Injection molding is a "tale of two costs." It is incredibly expensive to start, but arguably the cheapest way to manufacture at scale.

Whether it is "expensive" for you depends entirely on how many parts you plan to make.

1. The High Upfront Cost: Tooling

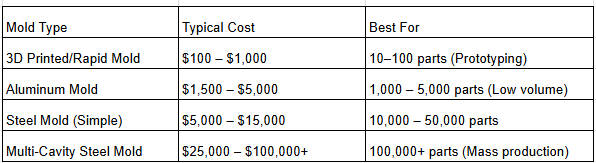

The most significant expense is the mold (tooling). Unlike 3D printing, which starts with a digital file, injection molding requires a physical metal tool (usually steel or aluminum) to be precision-machined.

2. The Low Unit Cost: Economies of Scale

Once the mold is paid for, the cost per part drops drastically. This is because the "variable costs"—the plastic resin and the electricity to run the machine—are very low.

At100 parts: You might pay $20.00 per part(because you're still paying off the mold).

At 10,000 parts: The cost might drop to $2.00 per part.

At 100,000 parts: The cost can be as low as $0.20 per part.

3. Factors That Drive Prices Up

If you are trying to keep costs down, watch out for these "price multipliers"

Complexity: Features like undercuts (parts that can't easily slide out of the mold) require "side-actions" or moving pieces in the mold, which can double the tooling price.

Surface Finish: A high-gloss or specific textured finish requires manual polishing of the mold, adding labor costs.

Material Choice: "Commodity" plastics like Polypropylene (PP) are cheap (approx. $0.90–$1.30/lb), while "Engineering" plastics like PEEK or Polycarbonate can cost 5x to 10x more.

Part Size: Larger parts require larger molds and higher-tonnage machines, which are more expensive to operate.

When to Choose Injection Molding?

Use it if: You need more than 1,000 units, require high strength, or need a "store-shelf" retail finish.

Avoid it if: You are still iterating on your design (changing a metal mold is very expensive) or if you only need a few dozen pieces. In those cases, 3D printing or CNC machining is much cheaper.