Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is die casting environmentally friendly?

Die casting is often considered one of the most environmentally friendly high-volume manufacturing processes, primarily due to its reliance on infinite recyclability and material efficiency.However, it is a high-energy process that depends heavily on the type of fuel used and the material being cast.

The "Green" Advantages

Die casting excels in several sustainability categories compared to other methods like sand casting or plastic injection molding.

1.Infinite Recyclability: Unlike plastics, which degrade each time they are recycled, the metals used in die casting (aluminum, zinc, and magnesium) can be melted and reused indefinitely without losing their mechanical properties.

2.Energy Savings from Scrap: Recycling aluminum requires only 5% of the energy needed to produce "virgin" aluminum from ore. Most die casting today uses a high percentage of post-consumer recycled material.

3.Near-Net Shape: The process is so precise that parts come out of the mold almost finished. This minimizes "swarf" (metal shavings) and waste that would otherwise be created by heavy machining.

4.Long-Life Tooling: A single steel die can produce hundreds of thousands of parts. This spreads the "environmental cost" of making the tool over a massive number of units.

The Environmental Challenges

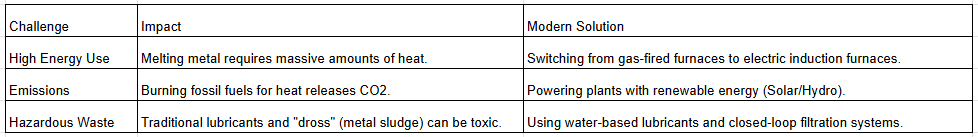

While the materials are sustainable, the process itself has a footprint that manufacturers are actively working to reduce.

Material Comparison: Zinc vs. Aluminum

If your goal is the lowest possible environmental impact, the choice of metal matters:

1.Zinc (The Eco-Winner): Zinc has a much lower melting point (419C) than aluminum (660C). This means it requires significantly less energy to melt, results in faster cycletimes, and causes less wear on the molds (which extends their life).

2.Aluminum (The Lightweight Winner): While it takes more energy to melt, aluminum'slightweight nature makes it more eco-friendly for the lifecycle of the product. For example, using aluminum parts in cars reduces vehicle weight, which lowers fuelconsumption and emissions over years of use.

Summary

Die casting is environmentally friendly because it supports a circular economy. It turns scrap metal into high-performance parts with very little waste. It is "unfriendly" only when powered by dirty energy or when using virgin metals instead of recycled ones.