Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Which industries use hot die casting technology?

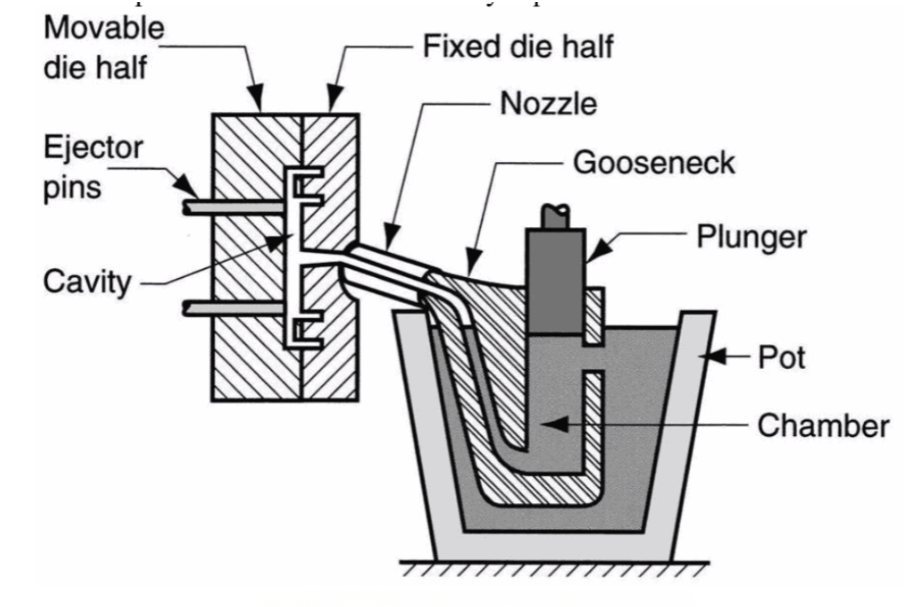

Hot chamber die casting (also commonly referred to as hot die casting) is a high-pressure metal casting process best suited for low-melting-point alloys like zinc, magnesium, tin, and certain lead-based alloys. It enables fast production cycles, excellent surface finish, and intricate details, making it ideal for small to medium-sized precision components.

Here are the main industries that heavily utilize hot chamber die casting:

1. Automotive Industry

Used for lightweight, durable parts such as engine components, transmission parts, brackets, interior fittings, and decorative trim elements.

Here are some typical zinc die-cast automotive components produced via hot chamber die casting:

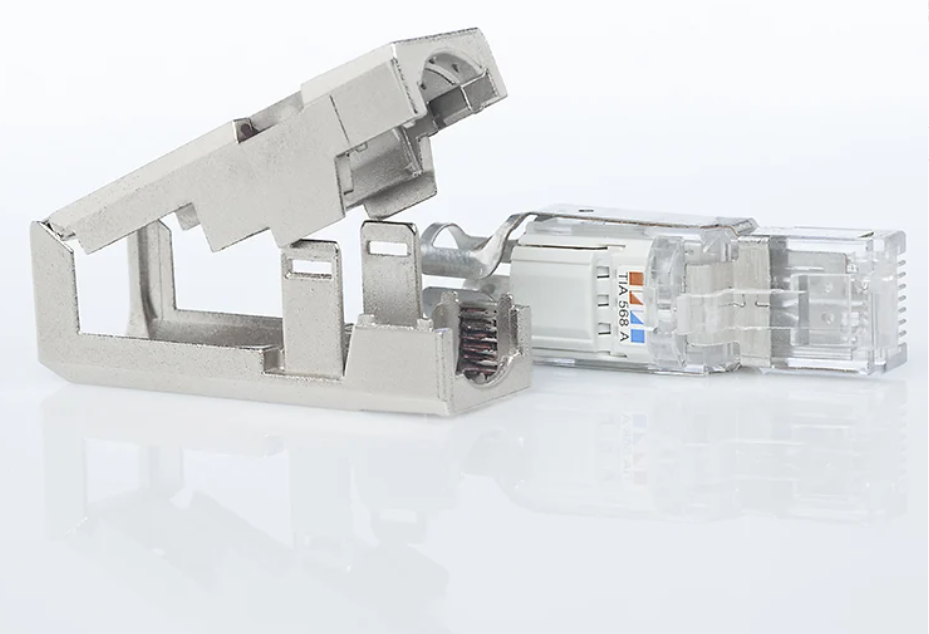

2. Electronics & Consumer Electronics

Widely applied for manufacturing casings, housings, connectors, heat sinks, and precision parts for smartphones, laptops, gadgets, and other devices — thanks to the process's superior dimensional accuracy and smooth finishes.

Examples of zinc die-cast parts commonly used in electronics:

3. Consumer Products & Appliances

Common for producing items like toys, hardware (e.g., gears, knobs), household appliances, sink faucets, plumbing fittings, and decorative elements.

4. Industrial Machinery & Equipment

Used to create durable, precise parts such as gears, bearings, pneumatic/hydraulic components, and small machinery housings.

Other Notable Industries

Aerospace — lightweight structural components and fittings (though less dominant than cold chamber for larger parts)

Medical Devices — precision housings, connectors, and small components

Plumbing & Hardware — faucets, valves, and connectors

Telecommunications — RF shielding and small enclosures

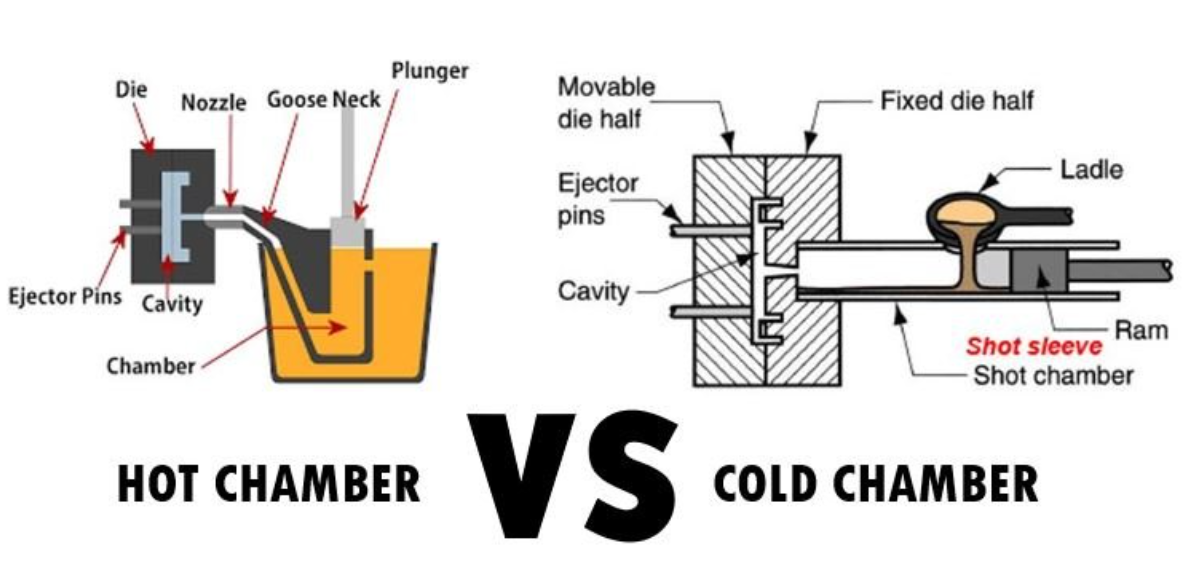

This process is not typically used for high-melting-point metals like aluminum (which require cold chamber die casting for larger/stronger parts in automotive and aerospace applications).

Here is a visual overview of a typical hot chamber die casting machine in action:

And a comparison diagram showing hot vs. cold chamber setups:

Hot chamber die casting excels in high-volume production of detailed, thin-walled parts where speed and cost-efficiency matter most! If you're exploring this for a specific project (like prototyping or mass production), feel free to share more details.