Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to medical device prototyping?

Medical device prototyping is a highly specialized, iterative process that differs significantly from regular consumer product prototyping due to strict safety requirements, biocompatibility concerns, and heavy regulatory oversight (FDA in US, EU MDR/CE marking in Europe, etc.).

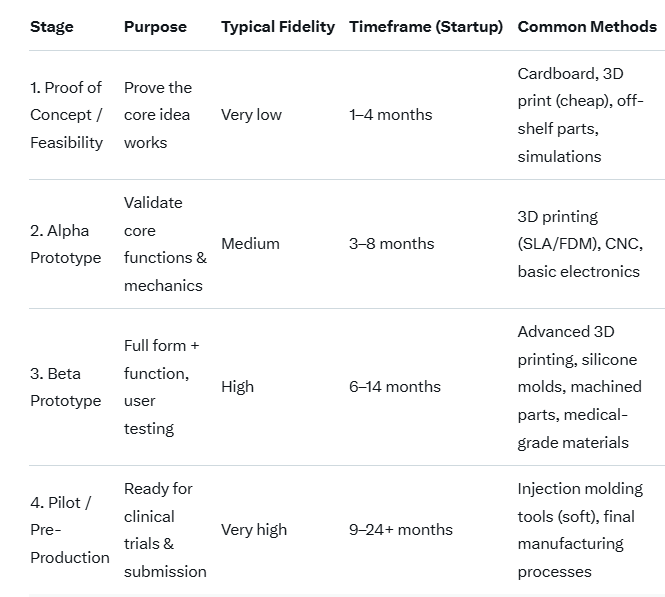

Typical Stages of Medical Device Prototyping

Most Popular Prototyping Methods in 2025–2026 (Medical Field)

1.3D Printing (still #1 for speed)

SLA (stereolithography) → best surface finish & accuracy

MJF / SLS → good for functional nylon parts

Medical-grade resins (biocompatible, sterilizable) now widely available

Very fast iteration (days instead of weeks)

2.CNC Machining

Best for: metal parts, tight tolerances (±0.01 mm), real engineering plastics (PEEK, Ultem, Radel)

Medical-grade metals: 316L stainless, titanium, CoCr

3.Silicone/Urethane Casting (soft tooling)

Bridge between 3D printing and injection molding

20–150 pieces with production-like appearance & feel

4.Injection Molding (rapid/aluminum tools)

Used earlier than most people think (already at beta stage for serious projects)

Critical for final material validation & regulatory submission

5.Hybrid approaches (most common reality)

3D printed housing + CNC machined critical components + commercial off-the-shelf electronics

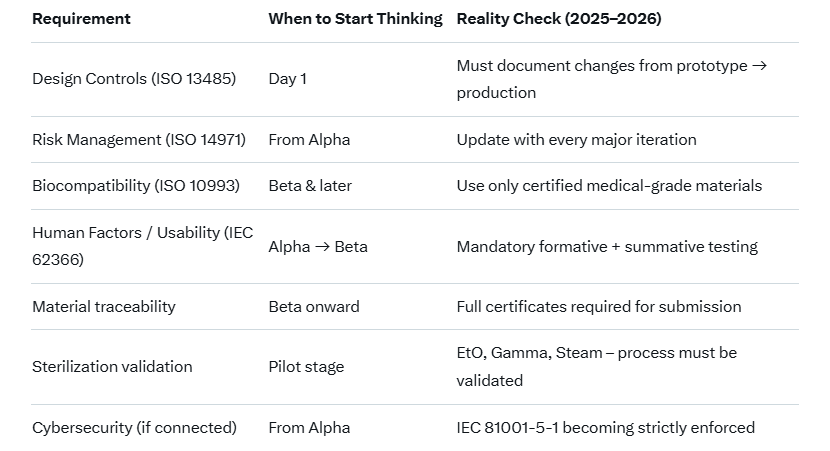

Critical Regulatory & Material Considerations (Don't Skip These!)

Realistic Advice for Startups (2025–2026)

1.Budget reality

Good functional medical prototype journey → usually $80k–$400k+ (depending on complexity)

2.Fastest realistic timeline (very disciplined team)

Concept → working Beta prototype ready for early clinical feedback → 12–20 months

3.Most common fatal mistakes (avoid them!)

Using non-medical-grade materials too long → big re-design later

Ignoring usability/human factors until too late

Switching manufacturing method at pilot stage without bridging data

No design history file / poor documentation

Trying to do everything in-house without medical-grade manufacturing experience

4.Smart startup strategy in 2025

Phase 1: Cheap & fast (3D print + off-shelf) → prove concept & get funding

Phase 2: Partner with experienced medical prototyping company (they know ISO 13485 workflow)

Phase 3: Early regulatory consultant (huge time & money saver)