Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to cast aluminum prototypes?

Casting aluminum prototypes is a versatile way to test designs, material properties, and fitment before committing to expensive high-volume production tooling. The method you choose depends on your prototype’s complexity, the required mechanical properties, and your budget.

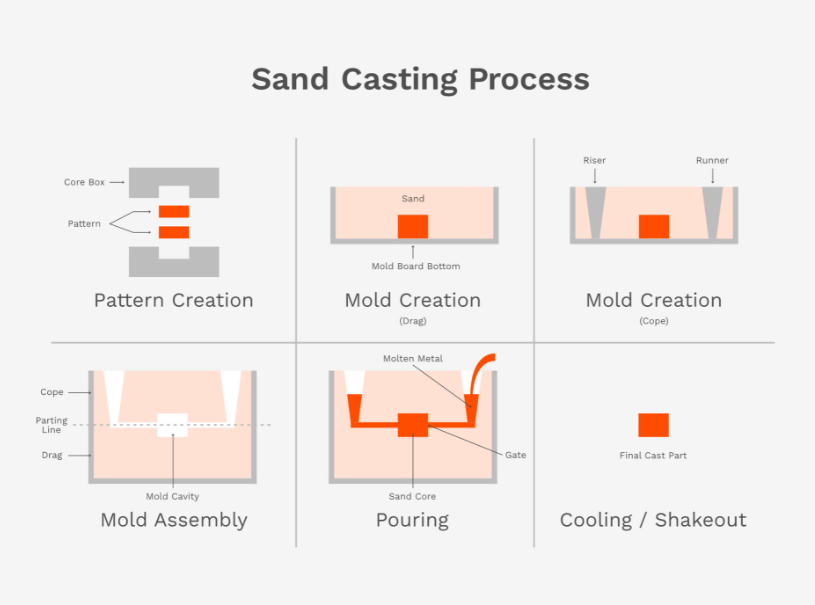

1. Sand Casting (Best for Speed & Larger Parts)

Sand casting is the most common method for early-stage prototyping. It involves packing a sand-binder mixture around a "pattern" (a physical model of your part) to create a cavity.

Process: Molten aluminum is gravity-fed into the sand mold.

Best for: Large, simple parts and rapid iterations.

Advantage: Very low tooling costs; patterns can be 3D printed quickly to skip traditional wood/metal pattern making.

Limitation: Rougher surface finish and lower dimensional accuracy compared to other methods.

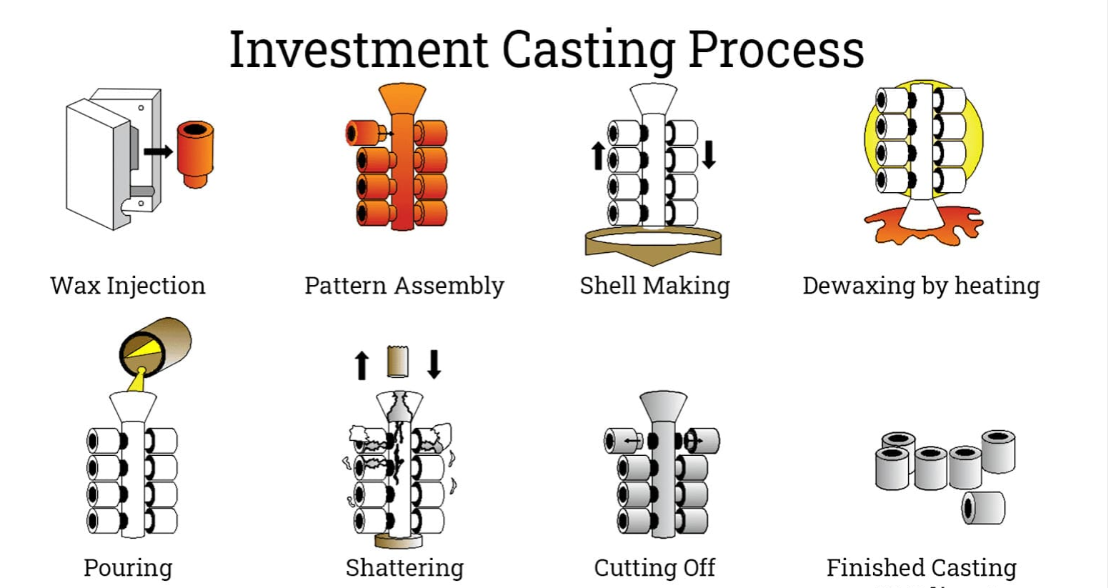

2. Investment Casting (Best for High Detail)

Also known as "lost-wax" casting, this is the gold standard for intricate prototypes that require a smooth finish.

Process: You create a sacrificial pattern (traditionally wax, but now often 3D printed resin). This pattern is dipped in a ceramic slurry to create a shell. The pattern is melted out, leaving a high-precision cavity for the aluminum.

Best for: Small, complex parts with thin walls and tight tolerances.

Advantage: Exceptional surface finish and detail; often requires no secondary machining.

3. Plaster Mold Casting

This is similar to sand casting but uses gypsum plaster instead of sand.

Process: The liquid metal is poured into a plaster mold, which provides a much smoother surface than sand.

Best for: Prototypes that need to simulate the look of a die-cast part without the die-casting price tag.

Advantage: Better surface finish and dimensional control than sand casting.

4. Hybrid 3D Printed Molds

Modern prototyping often uses "Digital Casting" to merge 3D printing with traditional foundry work.

Binder Jetting: 3D printers can print the sand mold itself directly from a CAD file, eliminating the need for a physical pattern entirely.

Direct Ceramic Printing: High-end systems can 3D print ceramic molds that can withstand molten aluminum immediately, allowing for a "CAD-to-metal" workflow in just a few days.

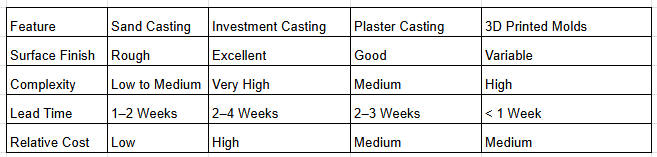

Comparison of Methods: