Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is pressure reduction in injection molding?

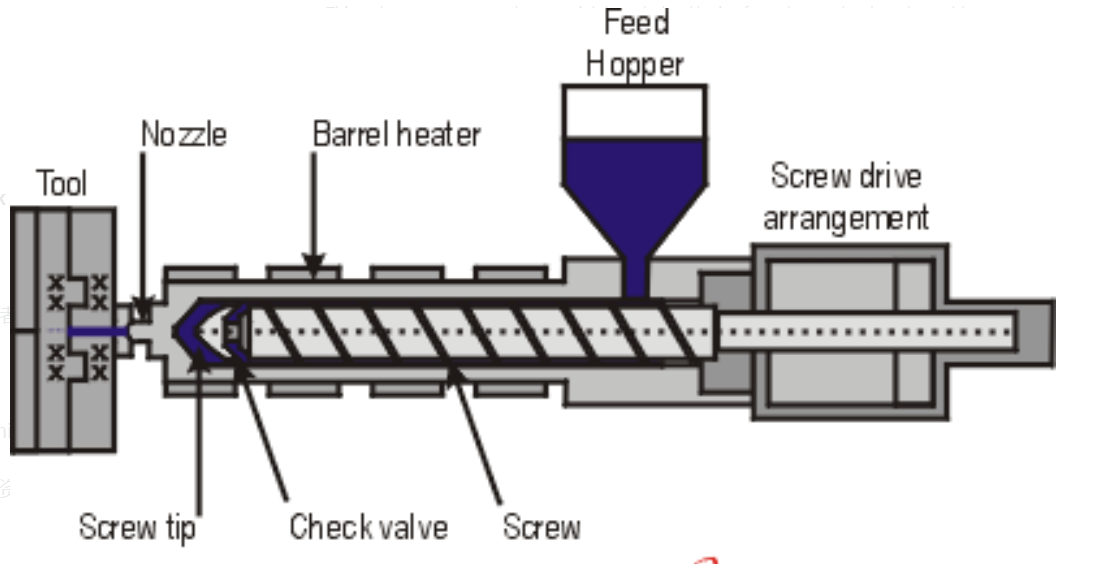

Decompression in injection molding (also called suck-back) is a controlled backward movement of the screw after plasticizing (dosing/metering) and/or after the injection & holding phase.Its main purpose is to relieve residual pressure in the melt in front of the screw, preventing several common problems.

Main Types of Decompression

1.Decompression after dosing/plasticizing (most common)

→ Happens right after the screw finishes rotating and preparing the shot volume

→ The screw moves back a few millimeters (typically 2–15% of screw diameter)

→ This reduces pressure so the material doesn't drool/string from the nozzle when the mold opens or during mold movement

Here are some typical screw positions during the cycle (including decompression phase):

2.Decompression after injection/holding (less common, used in specific cases)

→ After packing/holding phase, a small suck-back is done before mold opening

→ Helps reduce nozzle drool and gate vestige in some hot-runner systems

Why is Decompression Important? (Key Benefits)

1.Prevents drooling and stringing from the nozzle → cleaner molding area, less waste

2.Stops material from leaking into the sprue/gate when the mold is open

3.Helps maintain consistent shot weight by keeping the check ring (non-return valve) seated forward

4.Reduces wear on the check ring / non-return valve

5.In hot-runner molds → very important for controlling pressure and avoiding overpacking

Typical Settings & Rules of Thumb

1.Distance: Usually 2–10 mm (most often 3–8 mm), or ≈ 5–15% of screw diameter

2.Rule of thumb: Often set to slightly more than the travel distance of the check ring (≈1.0–1.5× check ring stroke)

3.Too little → drooling, inconsistent shot size, pressure spikes

4.Too much → sucks in air → splay, bubbles, voids, silver streaks, inconsistent filling

In short:

1.Decompression is a small but very important process parameter.

2.When set correctly → cleaner production, more stable process, longer life of check ring and more consistent parts.

3.When ignored or set wrong → drooling, splay, weight variation, and unnecessary defects.Many experienced molders consider proper decompression one of the "hidden" keys to a truly robust and repeatable injection molding process.