Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Selection of Medical Device Prototype Manufacturing Methods

Choosing the right manufacturing method for a medical device prototype is a high-stakes balancing act. You need to weigh speed and cost against biocompatibility and regulatory compliance.

Here is a breakdown of the most effective methods used in the industry today, categorized by their strengths and specific applications.

1. 3D Printing (Additive Manufacturing)

This is the gold standard for early-stage "look and feel" prototypes and complex geometries that are impossible to machine.

Stereolithography (SLA): Best for high-resolution, smooth finishes (e.g., dental models, hearing aids). Uses light-curable resins.

Selective Laser Sintering (SLS): Uses nylon powder to create durable, functional parts. No support structures are needed, making it great for complex internal channels.

Fused Deposition Modeling (FDM): Most affordable for basic form testing, though it lacks the precision for tight-tolerance medical components.

2. CNC Machining

When your prototype needs to be made out of "production-grade" materials like Titanium, Stainless Steel (316L), or high-performance plastics (PEEK, UHMWPE), CNC is the way to go.

Pros: Incredible precision and the ability to use the exact material intended for the final implant or tool.

Cons: Higher cost per unit and more design constraints compared to 3D printing.

Best For: Surgical instruments, orthopedic implants, and housings for electronic devices.

3. Rapid Injection Molding

If you are moving toward Verification and Validation (V&V) testing, you need parts that behave like the final product. Rapid tooling uses aluminum molds instead of steel to cut lead times from months to weeks.

Why use it: It allows you to test the actual "molded-in" stresses and material properties that 3D printing can’t replicate.

Best For: Disposable components, syringes, and high-volume clinical trial samples.

4. Vacuum Casting (Urethane Casting)

Think of this as the middle ground between 3D printing and injection molding. A 3D-printed master pattern is used to create a silicone mold.

The Benefit: You can produce 10–50 parts that look and feel like injection-molded plastic without the high tooling cost.

Best For: Overmolding (e.g., soft-touch handles on rigid tools) and early user-interface testing.

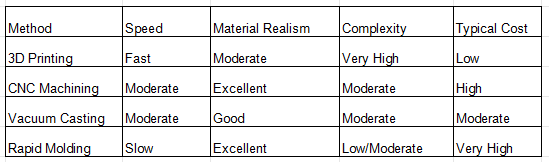

Decision Matrix: Which one do you need?