Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Why Use Prototype Plastic Injection?

Prototype plastic injection molding is the middle ground between 3D printing and full-scale mass production. It’s essentially a "dress rehearsal" for your final product, using the same materials and processes you'll use in the real world, but at a fraction of the traditional cost and lead time.

Here is why it’s a critical step in the manufacturing process:

1. Material Authenticity

While 3D printing is great for shape, the materials often lack the mechanical properties of final production plastics. Prototype injection molding uses production-grade resins (like ABS, Polycarbonate, or Nylon). This allows you to test:

Structural Integrity: Will it snap under pressure?

Chemical Resistance: How does it react to oils or cleaning agents?

Heat Deflection: Does it melt in a hot car?

2. Speed to Market (Bridge Tooling)

Building a hardened steel production mold can take 10 to 12 weeks. A prototype mold—often made from aluminum or soft steel—can be ready in 2 to 4 weeks.

Bridge Tooling: It "bridges" the gap, allowing you to start selling or testing while your high-volume mold is still being machined.

3. Validating Design for Manufacturability (DFM)

A design might look perfect in CAD, but physics can be a harsh critic. Prototype molding helps you identify "molding defects" early, such as:

Sink Marks: Thick areas that shrink and create dimples.

Warping: Parts twisting as they cool.

Knit Lines: Where two flows of plastic meet and create a weak point.

4. Low-Volume Cost Efficiency

If you only need 100 to 2,000 parts, a full-scale production tool (which can cost $50,000+) is overkill. Prototype tooling offers a lower entry cost, making it the most economical way to get high-quality parts for:

Clinical trials

Beta testing with real users

Regulatory certifications (UL, FDA, etc.)

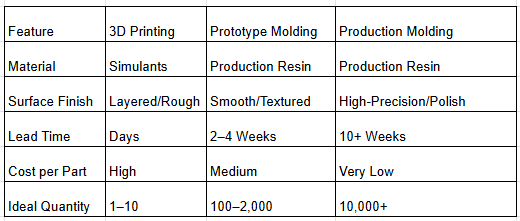

Comparison at a Glance