Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to choose a prototype plastic manufacturing process?

Choosing the right plastic prototyping process is a balance between speed, cost, and how closely you need the part to mimic the final product. If you pick a method that's too high-fidelity early on, you waste money; if you pick one that's too flimsy for testing, you waste time.

Here is a breakdown to help you navigate the options.

1. Define Your Prototype Stage

Before looking at machines, ask yourself what the prototype needs to do.

Proof of Concept: Does it just need to show the shape? (Low fidelity, cheap).

Functional Prototype: Does it need to snap together, hold weight, or resist heat? (Medium fidelity).

Pre-production: Does it need to look and feel exactly like the shelf-ready product? (High fidelity).

2. Compare Common Manufacturing Processes

3D Printing (Additive Manufacturing)

Best for rapid iterations and complex geometries that are impossible to machine.

FDM (Filament): Cheapest; good for basic shapes and "fit" tests.

SLA (Resin): High detail and smooth surface finish; great for visual models.

SLS (Powder): Tough, functional nylon parts; no support structures needed.

CNC Machining (Subtractive)

Best for structural integrity and material "realness."

Pros: Uses actual production-grade plastics (like PEEK, Acetal, or Nylon). Extremely precise.

Cons: Expensive for complex internal shapes; more waste material.

Vacuum Casting (Urethane Casting)

The "bridge" between prototyping and production.

How it works: A 3D-printed master is used to create a silicone mold, which is then filled with resin.

Pros: Excellent surface finish; can mimic over-molding and different shore hardness (rubbery to rigid).

Rapid Tooling (Prototypal Injection Molding)

Best for testing the actual manufacturing process.

Pros: Uses aluminum molds instead of steel to save cost. Best for runs of 100+ parts.

Cons: High upfront cost compared to other prototype methods.

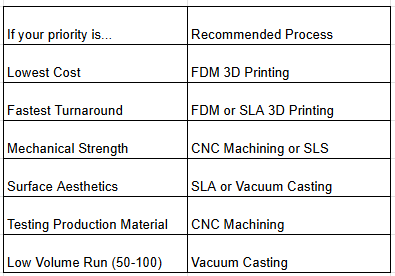

3. Decision Matrix: Which one to pick?