Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Prototype Plastic Injection Process Overview

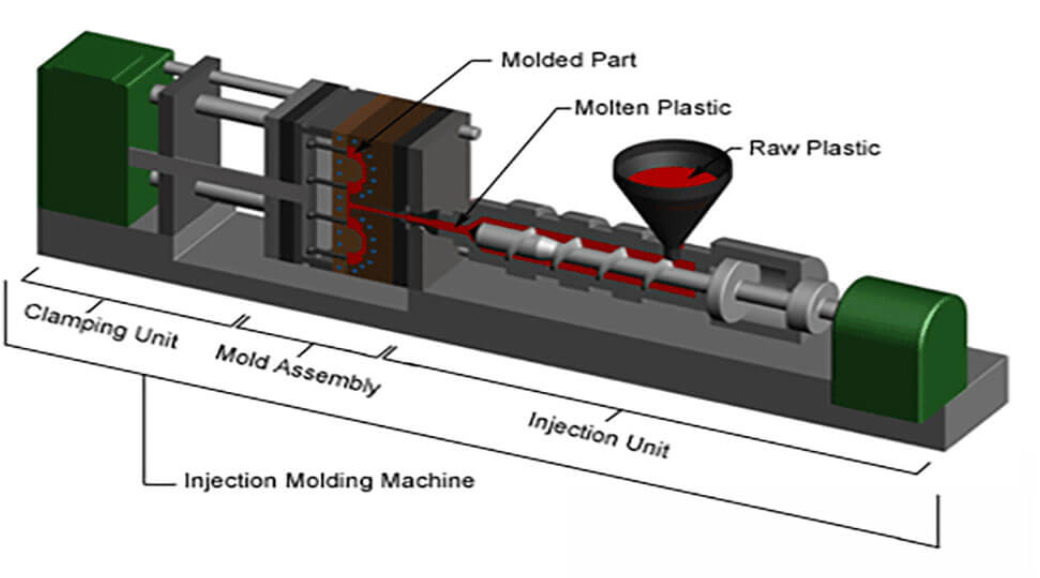

Prototype Plastic Injection Molding Process OverviewPlastic injection molding is a widely used manufacturing process for producing precise plastic parts by injecting molten material into a mold. For prototyping, the process is adapted for lower volumes, faster turnaround, and cost efficiency—often using aluminum molds (instead of steel) to create production-like parts for testing form, fit, function, and material performance before full-scale production.While the core cycle mirrors standard injection molding, prototype versions emphasize rapid tooling (e.g., CNC-machined aluminum molds) and smaller runs (dozens to thousands of parts).

Key Steps in the Prototype Plastic Injection Molding Process

1.Part Design and Mold Preparation

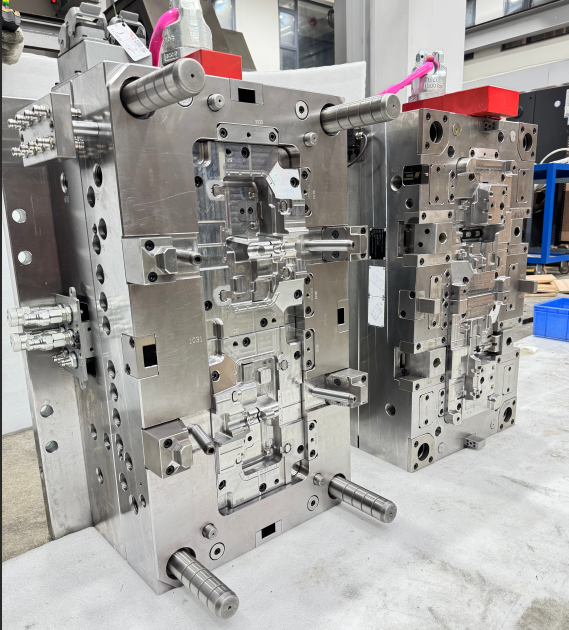

Start with a finalized 3D CAD model of the part. Design considerations include draft angles, wall thickness uniformity, and gate locations to ensure good moldability. For prototyping, a simplified, single-cavity (or low-cavity) mold is designed and quickly machined from aluminum or similar soft metals. This step is faster and cheaper than production steel tooling.

2.Material Preparation

Thermoplastic resin pellets (e.g., ABS, PP, PC, or Nylon) are loaded into the machine's hopper. These are the same production-grade materials used later, allowing accurate prototyping for mechanical and thermal testing.

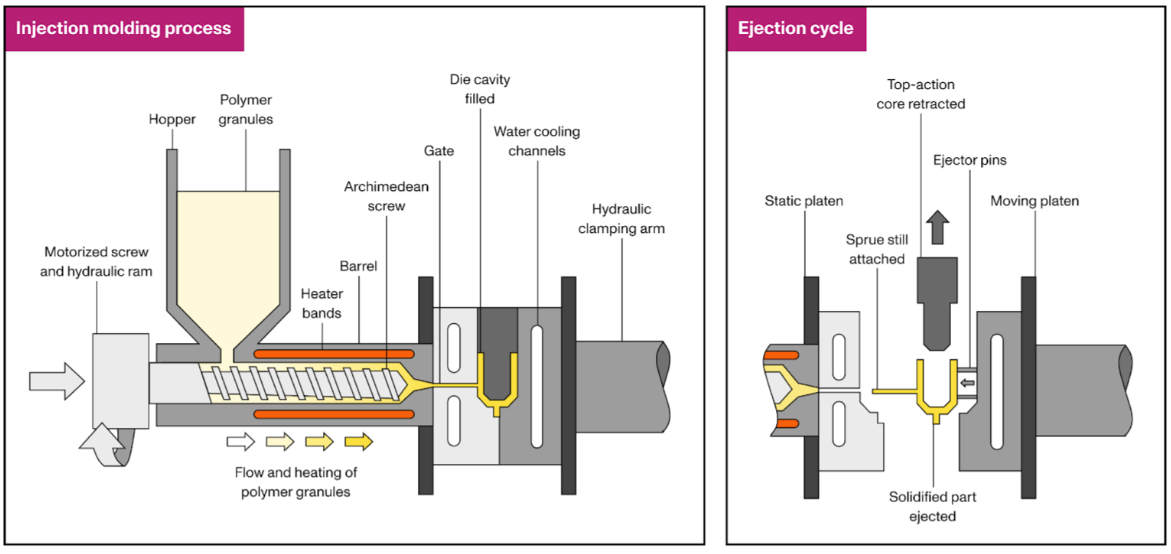

3.Injection Molding Cycle (The Core Repeating Process)

This cycle repeats for each part and typically includes these main stages:Clamping — The mold halves (fixed and movable platens) are closed and clamped under high pressure to withstand injection forces and prevent flash (excess material leakage).

Injection — Plastic pellets are fed from the hopper into a heated barrel. A reciprocating screw melts and mixes the material via heat and shear. The screw then pushes the molten plastic under high pressure through the nozzle, runners, and gates into the mold cavity.

Packing/Holding — Additional pressure is applied briefly to pack more material and compensate for shrinkage as the plastic cools.

Cooling — The mold (often with built-in cooling channels) removes heat, solidifying the plastic into the final shape. Cooling time is usually the longest part of the cycle and critical for part quality.

Ejection — The mold opens, and ejector pins push the solidified part out. The cycle resets for the next shot.

Prototype-Specific Advantages

Faster and cheaper tooling — Aluminum molds can be produced in days/weeks vs. months for steel.

Production-equivalent parts — Use real materials and process parameters for reliable testing.

Bridge to production — Prototype molds can sometimes serve low-volume runs or validate designs before investing in durable steel production tooling.

This process enables quick iteration, functional validation, and risk reduction in product development. If you're working on a specific prototype project, factors like part complexity, material choice, and volume will influence exact setup and costs.As a rapid prototyping specialist, Shenzhen Alu Rapid Prototype Precision Co., Ltd. offers expertise in prototype injection molding.