Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is the purpose of prototype plastic injection?

Prototype plastic injection molding serves a bridge between a raw concept and full-scale production. Think of it as the "stress test" for your design—it’s where you find out if your part actually works, fits, and looks the way you intended before you drop tens of thousands of dollars on permanent steel tooling.

Here is why it is a critical step in the manufacturing process:

The Primary Purposes

1. Functional Testing and Validation

Unlike 3D printing, which often uses different materials than the final product, prototype injection molding allows you to use the actual production-grade resin. This means you can test:

Mechanical Strength: Will the snap-fit break?

Thermal Resistance: Can it handle the heat of the engine bay?

Chemical Compatibility: Does the plastic degrade when it touches cleaning agents?

2. Design for Manufacturing (DfM)

It’s one thing for a part to look good in CAD; it’s another for it to eject from a mold without warping. Prototyping reveals:

Wall Thickness Issues: Identifying "sink marks" or shadows.

Gate Placement: Figuring out where the plastic enters the mold to avoid ugly blemishes.

Draft Angles: Ensuring the part doesn't get stuck in the tool.

3. Market Testing and Aesthetics

If you are pitching to investors or showing a product at a trade show, a 3D-printed part often looks like... well, a 3D-printed part. Prototype molding provides:

Production-Quality Finish: High-gloss, textured, or transparent finishes.

Consumer Feedback: Letting real users handle a "final-feeling" product to gather ergonomic data.

4. Bridge Production

Sometimes, you need 500 units now to start selling, but your high-volume "hard" tool won't be ready for three months. Prototype molding (often using aluminum tools) can churn out these initial units quickly to get you to market faster.

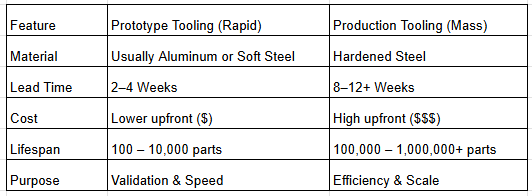

Comparison: Prototype vs. Production Tooling