Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to cast aluminum prototypes?

Casting aluminum prototypes is a common need in product development, especially for functional testing, fit checks, and low-volume production before committing to expensive production tooling (like hard die casting dies).Here are the most practical and widely used methods for aluminum prototype casting, roughly ordered from most common / fastest for prototypes to more production-oriented approaches. The best choice depends on your part complexity, required tolerances, surface finish, quantity (1–50 pieces typical for prototypes), mechanical properties needed, and budget/lead time.

Most Popular Methods for Aluminum Prototypes

1.Plaster Mold Casting (Rubber Plaster Mold / RPM)

One of the sweet spots for aluminum prototypes (especially 1–100 pieces).

Uses a reusable rubber pattern/master → plaster molds are made from it → molten aluminum poured by gravity.

Excellent surface finish (~63–125 RMS), good dimensional accuracy, thin walls possible, captures fine details better than sand.

Lead time: often 1–4 weeks for first parts. Tooling cost moderate (much cheaper than die casting).

Very common in China (including Shenzhen area) for rapid aluminum prototypes.

2.Sand Casting (including No-Bake / Air-Set / Chemically Bonded Sand)

Classic low-cost method for prototypes.

Pattern (wood, 3D printed, CNC machined, etc.) → sand mold packed around it → pour molten aluminum.

Good for larger parts, complex shapes, low quantity.

Rougher surface finish (250–500 RMS), more generous tolerances (±0.030" + per inch), needs more machining allowance.

Fastest & cheapest for very low volume or very large prototypes. Lead time: days to 2–3 weeks.

3.Investment Casting with Rapid Patterns (Lost-Wax with 3D Printed / SLA / Resin Patterns)

Modern rapid version: Instead of expensive aluminum tooling for wax patterns, print the pattern directly (SLA, PolyJet, etc.) or print the mold.

Creates ceramic shell → burn out pattern → pour aluminum.

Outstanding detail, excellent surface finish (63–125 RMS), tight tolerances (±0.005" typical), thin walls, no draft needed in many cases.

Closest in properties and appearance to final production investment-cast or die-cast parts.

Lead time: 2–6 weeks typical for rapid versions. Cost higher than plaster/sand but excellent quality.

4.Rapid/Prototype Die Casting (Soft Tooling / Hybrid / Semi-Solid)

Uses aluminum or P20 steel "soft" dies (instead of full H13 hardened production dies).

High pressure injection like production die casting but with cheaper/faster tooling.

Very close to final production parts in strength, finish, and tolerances.

Best when you plan high-pressure die casting in production and need prototypes that match it closely.

Lead time: 3–8 weeks, higher cost than plaster/sand but still much less than full production tooling.

5.Other / Hybrid Techniques (less common for true casting but worth mentioning)

Spin / Centrifugal Casting — for certain geometries, good surface, fast for low volume.

Permanent Mold / Gravity Die Casting with rapid tooling — bridges prototype to low-medium volume.

3D printed sand molds (very fast for sand casting prototypes).

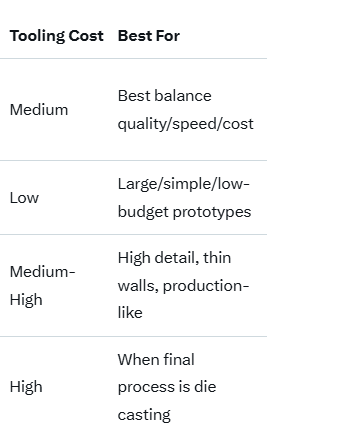

Quick Comparison Table for Aluminum Prototypes