Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is Characteristics of Traditional Prototyping?

Traditional prototyping refers to the physical or manual creation of early-stage models long before digital simulations became the industry standard. It’s the "hands-on" approach—think wood, clay, foam, or even breadboards for electronics.

Here are the defining characteristics that set traditional prototyping apart:

1. Physicality and Tangibility

The most obvious trait is that these prototypes are physical objects. You can touch them, hold them, and feel their weight.

Tactile Feedback: It allows designers to understand ergonomics (how a handle fits in a hand, for example) in a way a screen cannot.

Physical Testing: You can drop it, heat it, or put it in a wind tunnel to see how the material actually reacts.

2. Manual Craftsmanship

Traditional prototypes are often built by hand or using manual machinery (lathes, mills, saws).

Skill-Dependent: The quality of the prototype is directly tied to the craftsmanship of the builder.

Iterative "Sculpting": Changes are made by physically adding or removing material (subtractive or additive manual processes).

3. Fidelity Levels

Traditional prototyping is often categorized by how much it resembles the final product:

Low-Fidelity: "Rough-and-dirty" models made from cardboard or foam to test basic shapes and sizes.

High-Fidelity: Sophisticated models that look and function like the final product, often used for stakeholder presentations or final ergonomic testing.

4. Time and Resource Intensive

Unlike modern 3D printing (Rapid Prototyping), traditional methods usually take more time.

Material Waste: Subtractive methods (like carving a model out of a block of wood) result in significant scrap material.

No "Undo" Button: If you cut too much off a physical model, you often have to start over or find a creative way to patch it.

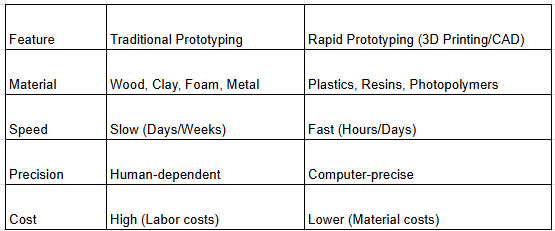

Comparison: Traditional vs. Rapid Prototyping