Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is rapid cnc machining?

Rapid CNC machining (also called quick-turn CNC machining or fast CNC machining) is a specialized form of CNC (Computer Numerical Control) machining optimized for speed and short lead times, while still delivering high precision and quality parts.It uses computer-controlled machines (like mills, lathes, or multi-axis centers) to subtract material from solid blocks of metal, plastic, or other materials, but with streamlined processes, optimized toolpaths, high-speed spindles, automated setups, and focused workflow to dramatically reduce production time compared to traditional CNC machining.

Key Characteristics of Rapid CNC Machining

Turnaround time: Parts often delivered in 1–7 days (sometimes as fast as 24–72 hours for simpler designs), versus weeks for conventional CNC jobs.

Typical applications — Ideal for:Rapid prototyping (functional testing, design validation, iteration)

Low-volume production

Bridge production (small batches before full tooling)

Custom one-off or end-use parts

Materials — Wide range including aluminum, stainless steel, titanium, brass, plastics (ABS, POM, nylon, PEEK), etc.

Precision — Maintains tight tolerances (often ±0.005 mm or better), similar to standard CNC, but speed is prioritized without major sacrifice in quality.

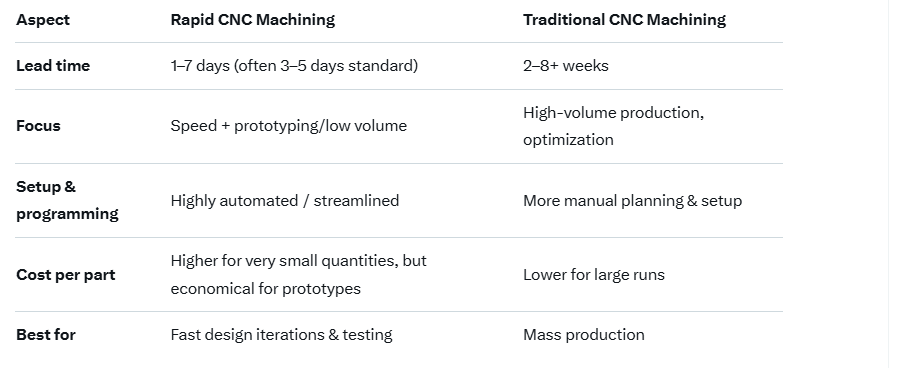

Rapid CNC vs. Traditional CNC Machining

Main Advantages

Extremely fast iterations — Engineers can test multiple design versions in days instead of months.

Production-grade materials & finishes — Parts match final production quality (unlike many 3D printing methods).

Complex geometries — Handles undercuts, fine details, and tight tolerances well.

No tooling investment — Unlike injection molding, no expensive molds needed.

Bridge to production — Easy transition from prototypes to small-batch or medium-volume runs.