Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is rapid cnc machining?

Rapid CNC (Computer Numerical Control) machining is essentially the "sprinter" version of traditional manufacturing. It focuses on producing high-quality, precision parts in days rather than weeks by streamlining the workflow from digital design to physical object.

While standard CNC machining is often geared toward high-volume production runs, Rapid CNC is optimized for speed, flexibility, and low-volume orders—perfect for prototyping or bridge production.

How It Works: From CAD to Part

1.The process relies on a digital-first approach that removes the bureaucratic and logistical "lag" found in traditional shops.

2.Digital Upload: You provide a 3D CAD (Computer-Aided Design) file.

3.Automated Quoting: Advanced software analyzes the geometry and provides an instant quote and DFM (Design for Manufacturability) feedback.

4.Toolpath Generation: Instead of manual programming, software automatically creates the instructions for the machine.

5.High-Speed Subtraction: A machine uses rotating tools to carve the part out of a solid block of material (plastic or metal) at high speeds.

Key Advantages

1.Speed: You can often get parts in hand within 1 to 3 business days.

2.Material Reality: Unlike 3D printing, which uses specialized resins or filaments, Rapid CNCuses production-grade materials (e.g., Aluminum 6061, Stainless Steel, PEEK, or Delrin).This means your prototype performs exactly like the final product.

3.Precision: It maintains the tight tolerances (+0.005" or better) required for aerospace,medical, and automotive applications.

4.Surface Finish: Parts come off the machine with excellent surface quality, reducing theneed for secondary processing.

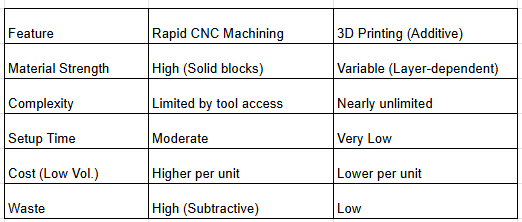

Rapid CNC vs. 3D Printing

While both are used for "rapid" work, they serve different needs: