Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is die casting equipment?

Die casting equipment refers to the specialized machinery and tooling used in the die casting process, a high-pressure metal casting method that forces molten non-ferrous metals (such as aluminum, zinc, magnesium, or copper alloys) into reusable steel molds (called dies) to produce precise, complex parts. This equipment enables the mass production of components with excellent dimensional accuracy, smooth surfaces, and intricate geometries, making it ideal for industries like automotive, electronics, aerospace, and consumer goods. The process originated in 1838 for printing type and has evolved into a cornerstone of modern manufacturing due to its efficiency for high-volume runs.

Key Components of Die Casting Equipment

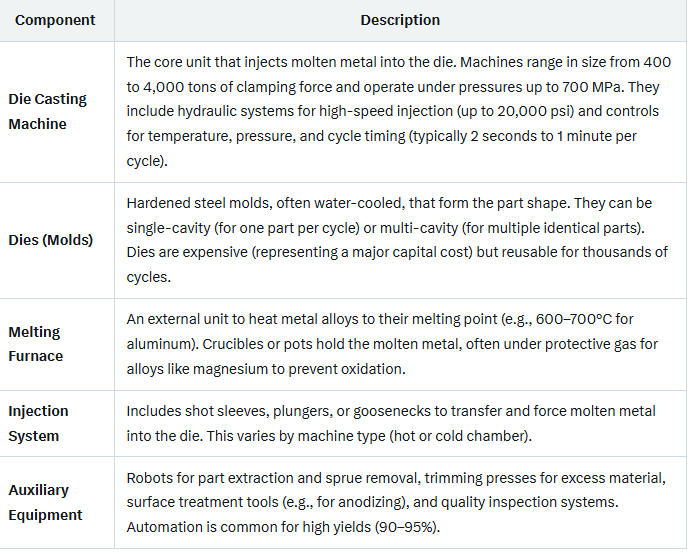

Die casting setups typically include a combination of machines, furnaces, and auxiliary tools. Here's a breakdown:

The high capital cost of this equipment (machines and dies can cost hundreds of thousands to millions) limits its use to large production volumes, but it minimizes waste and enables near-net-shape parts.

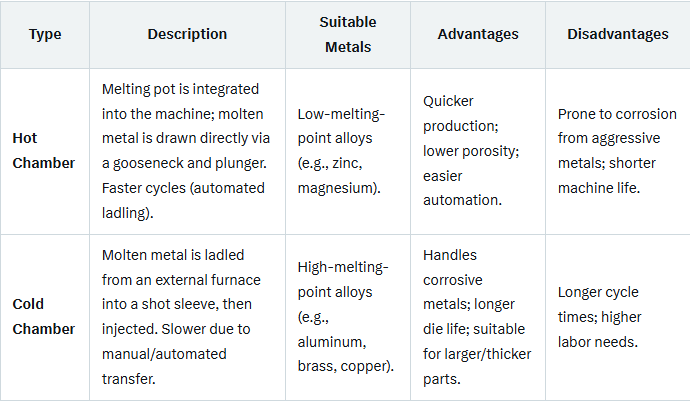

Types of Die Casting MachinesThere are two primary types, differentiated by how molten metal is handled:

Hot chamber is preferred for small, high-speed runs, while cold chamber excels in versatility for demanding alloys.