Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is die casting parts used for?

Die casting parts are precision-engineered metal components produced through a high-pressure casting process using reusable steel molds (dies). These parts are valued for their complex geometries, thin walls, high dimensional accuracy (tolerances as tight as ±0.001 inches), smooth surface finishes, and excellent mechanical properties like strength and ductility. They are typically made from non-ferrous alloys such as aluminum, zinc, magnesium, or copper, making them lightweight yet durable. This process is ideal for high-volume production, enabling cost-effective manufacturing of intricate parts that require minimal post-processing.Die casting originated in the 19th century for printing components and has since become essential for mass-producing robust, repeatable parts across industries. Below is an overview of key applications, grouped by sector, highlighting why die casting is preferred (e.g., for weight reduction, corrosion resistance, and efficiency).

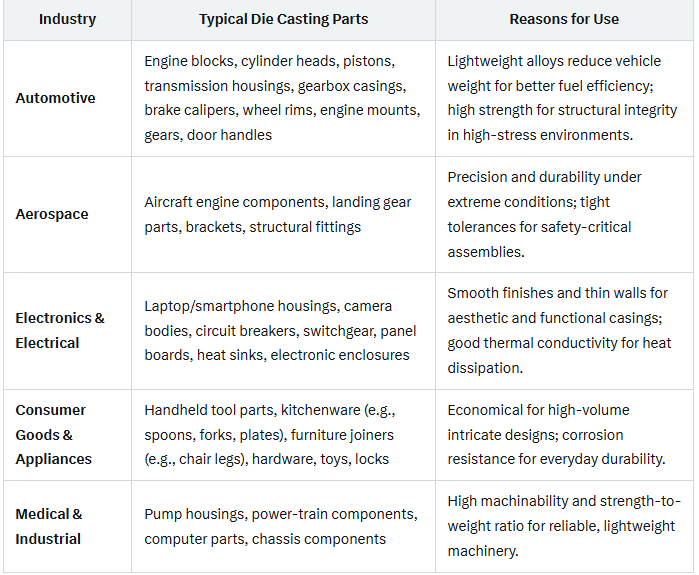

Common Applications by Industry

These applications leverage die casting's advantages, such as rapid cycle times (seconds to minutes per part) and minimal waste, making it suitable for producing thousands of identical components daily. For instance, magnesium alloys like AZ91D are favored in automotive for their 75% lighter weight than steel without sacrificing strength.