Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is permanent mold casting and die casting?

Both permanent mold casting and die casting are metal casting processes used to produce precise, high-quality metal parts, but they differ in methodology, applications, and characteristics.

Permanent Mold Casting

Definition: Permanent mold casting is a process where molten metal is poured into a reusable metal mold (typically made of steel or cast iron) under gravity or low pressure, without the high-pressure injection used in die casting. The mold is coated with a release agent to facilitate part removal and can be reused for thousands of cycles.

Die Casting

Definition: Die casting is a high-pressure casting process where molten metal is injected into a steel mold (die) under high pressure (1,000–30,000 psi) to produce complex, precise parts with excellent surface finish. It’s typically divided into high-pressure die casting (HPDC) and low-pressure die casting (LPDC), with HPDC being the most common.

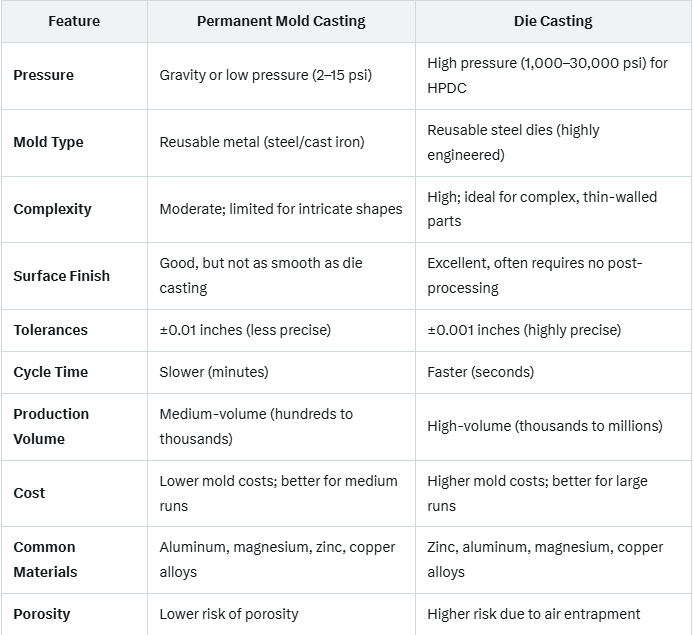

Key Differences Between Permanent Mold Casting and Die Casting