Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is the difference between die cast and cast iron?

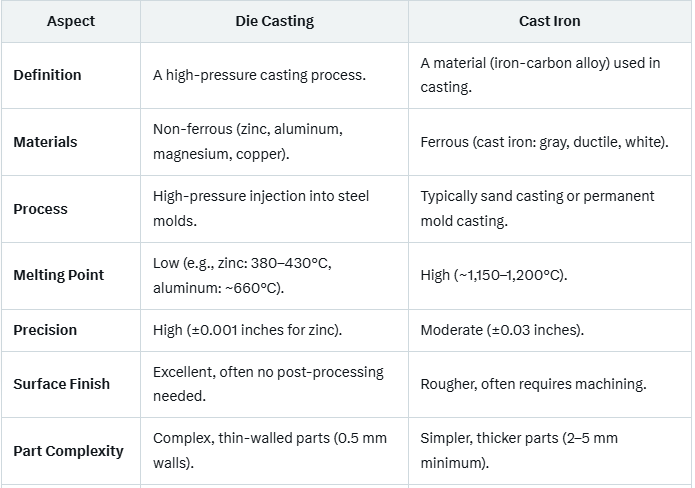

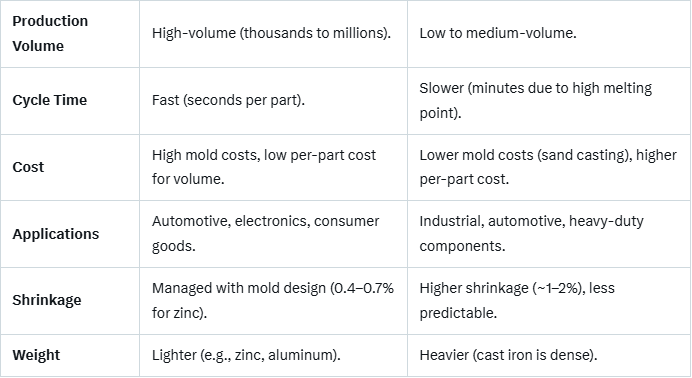

Die casting and cast iron refer to distinct concepts in manufacturing: die casting is a process, while cast iron is a material. However, the terms are often compared in the context of metal casting processes and the materials used. Below is a clear explanation of their differences, incorporating your prior interest in die casting (e.g., zinc die casting, shrinkage) and relevance to Shenzhen Alu Rapid Prototype Precision Co., Ltd.

1. Die Casting: A Manufacturing Process

Definition: Die casting is a high-pressure casting process where molten metal is injected into a reusable steel mold (die) under high pressure (1,000–30,000 psi) to produce precise, complex parts with excellent surface finish. It’s typically used with non-ferrous metals like zinc, aluminum, and magnesium.Key Characteristics:Process:Molten metal (e.g., zinc, aluminum) is forced into a mold at high pressure.

Rapid cooling and solidification produce parts in seconds.

The mold is reusable for thousands of cycles.

2. Cast Iron: A Material (and Associated Casting Processes)

Definition: Cast iron is a group of iron-carbon alloys with a carbon content greater than 2% (typically 2–4%), known for its strength, durability, and excellent castability. It’s typically formed using casting processes like sand casting, permanent mold casting, or occasionally investment casting, but not high-pressure die casting due to its high melting point (around 1,150–1,200°C or 2,100–2,200°F).

Key Differences Between Die Casting and Cast Iron