Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How much does injection molding cost?

Injection molding is a high-volume manufacturing process for producing plastic (or sometimes metal/ceramic) parts by injecting molten material into a custom mold. Costs can vary dramatically—from a few hundred dollars for simple prototypes to over $100,000 for complex, high-volume production setups—depending on factors like part design, material, production volume, and location. Generally, there's a high upfront fixed cost (primarily the mold) that's amortized over the run, making it economical for large quantities but less so for small batches.

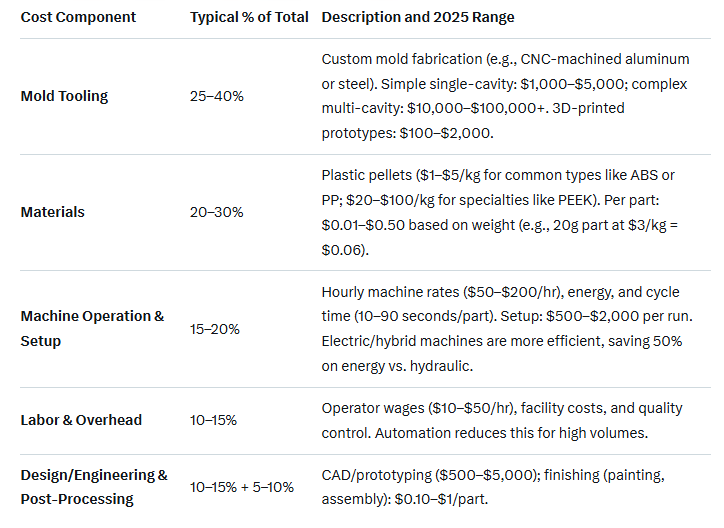

Total costs break down into fixed costs (e.g., mold tooling) and variable costs (e.g., materials, labor, and machine time). In 2025, expect slight increases due to material price fluctuations from global supply chains, but efficiencies in automation and energy use (e.g., electric machines) can offset this.

Key Cost Components

Here's a typical breakdown as a percentage of total project cost:

Factors Influencing Costs

1.Part Size & Complexity: Larger or intricate designs (e.g., undercuts, ribs) require pricier molds and longer cycles.

2.Production Volume: Low (under 1,000 parts): Higher per-unit cost due to unamortized tooling. High (10,000+): Economies of scale drop costs 50–80%.

3.Material Choice: Commodity plastics (e.g., PP at $1–$2/kg) are cheapest; engineering grades (e.g., PC at $2.50–$4/kg) add durability but cost more.

4.Location & Outsourcing: U.S./EU production is 20–50% higher than Asia due to labor; outsourcing to specialists can cut lead times but add markups.

5.Cycle Time & Efficiency: Optimized cooling channels shorten cycles, boosting output and reducing machine costs.

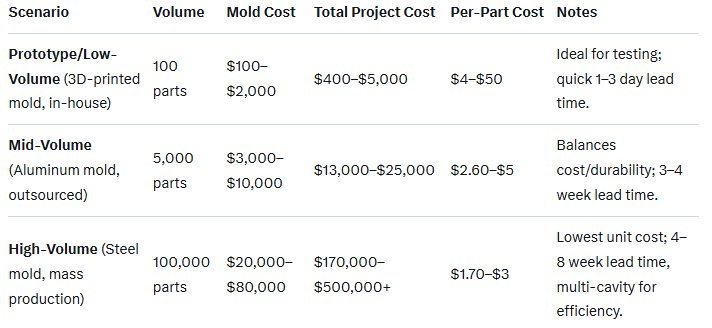

Per-Part Cost Examples

Per-part pricing decreases with volume as fixed costs spread out. Here's a comparison for a simple-to-moderate complexity plastic enclosure (e.g., 50g part, ABS material):

For complex parts (e.g., with tight tolerances), add 20–50% to these figures.